System spots damaged packages

Sensor producer SICK (Waldkirch, Germany) demonstrated a system at the LogiMAT trade fair in Stuttgart that automatically detects damaged packages and, if necessary, diverts them from automated lines for manual processing.

Damage to, or deformation of, packages is not readily detectable in automated warehouse and conveyor systems. In certain circumstances, such packages can no longer be handled automatically and must be manually removed from the system.

This causes material flow problems and profitability. In some cases, it could result in the warehouse and conveyor systems being damaged or, at least, temporarily blocked by a deformed package.

SICK's answer to this problem is its new system for contour verification, the VMS430, which it demonstrated at the LogiMAT logistics fair at the Stuttgart Neue Messe exhibition center in February this year.

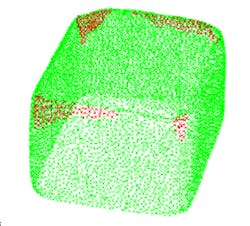

The SICK system consists of three LMS400 laser measurement heads and an intelligent evaluation system. Packages transported on a conveyor belt are automatically scanned when passing the laser scanner heads. The evaluation unit then estimates the bulges or dents on the package within a selected tolerance range. If the damage is too serious, a carton is automatically diverted off a conveyor system without any manual intervention.

The company sees potential for the VMS430 system in logistics, parcel shipment and the inspection of incoming goods.

Related items from Vision Systems Design that you might also find of interest.

1. Vision system checks milk containers for flash

Worldwide plastics manufacturer Logoplaste (Essex, UK) has worked closely with Sick UK (St Albans, UK) to reduce to nearly zero the number of defective blow-molded 2-litre milk containers delivered to its customer -- a major UK dairy products company.

2. Machine vision adds traceability to packaging

An automated vision system identifies cases of packed fruit and affixes barcode labels at a rate of more than 60 cases per minute.

-- Dave Wilson, Senior Editor, Vision Systems Design