Turnkey vision system enables in-line inspection of assembly and surface defects

Radiant Vision System’sVIS-I solution is a fully-integrated inspection station that utilizes a 29 MPixel CCD camera, bright field lighting, and programmable imaging software to detect subtle defects on complex assemblies and low-contrast parts and surfaces.

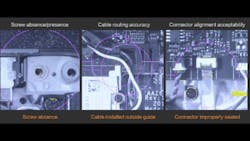

The system, which was honored with a Silver-level award in the 2017 Vision Systems Design Innovators Awards, features a ProMetric I29 integrated camera. The ProMetric I29 features a 6576 x 4384 cooled interline CCD image sensor, a dynamic range of 61 dB, and can defect defects that may go unnoticed by human inspectors, including light scratches on glass, gap variations of less than 1 mm between keys in a keyboard, or the presence or absence of tiny black screws from drill holes in a black component, according to the company.

Additionally, the VIS-I’s built-in software provides tools for assembly verification and gauging to ensure the manufacturing accuracy of a device and its components (tools include locate, measure, presence/absence, and edge detection) as well as surface inspection to detect defects like scratches, dents, and debris (employing photometric-based evaluation of gradient and contrast).

View more information on the VIS-I system.

Share your vision-related news by contacting James Carroll, Senior Web Editor, Vision Systems Design

To receive news like this in your inbox, click here.

Join our LinkedIn group | Like us on Facebook | Follow us on Twitter

Learn more: search the Vision Systems Design Buyer's Guide for companies, new products, press releases, and videos