System inspects indexable inserts

Off-the-shelf machine-vision cameras, frame grabbers, and software allow cutting tools to be rapidly inspected.

By Andrew Wilson, Editor

Aircraft engines, engine blocks, gears, and bearings are just a few of the products that require machining with precision cutting tools. Because these parts can vary in composition, size, and weight, many different cutting tools may be required to perform machining operations. However, these parts are susceptible to wear and must be replaced frequently. To reduce the cost of replacement, the tooling industry has adopted indexable inserts-cutting edges that are placed on the tool holder, which has both simplified tool handling and paved the way for innovations such as standard insert shapes and geometries designed to cut specific patterns in metal (see Fig. 1).

null

Inspection and handling

To handle parts efficiently, ROBOWORKER Automation has developed a system that automates the handling, inspection, and packaging of indexable inserts. According to Christian Härle, project manager at ROBOWORKER, the handling system encompasses all of these technologies in a multistage system. “In operation,” says Härle, “the system can handle parts of any shape, depending on the needs of the manufacturer. Parts with standard shapes such as square, rectangular, triangular, round, octagonal, hexagonal, pentagonal, or rhombic can be processed immediately without training. Special shapes can be taught easily by the operator from a training image.”

Sintered parts are placed on round coating trays-also done by a system installed by ROBOWORKER-and the trays are stacked and moved into an oven for coating. After coating, stacks of trays are removed from the oven, palletized to rectangular trays by another ROBOWORKER system, and washed. The most important task then is to inspect and pack the final product. “Depending on the nature of the parts being manufactured,” says Härle, “they are placed uniformly by row and column in the trays.” Up to 368 indexable inserts are placed in trays that accommodate between 9 and 23 rows and between 7 and 16 columns.

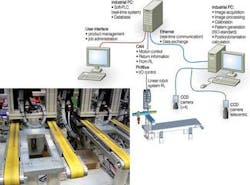

To properly inspect and pack vending boxes of indexable inserts, stacks of trays are automatically unloaded row by row from a ROBOWORKER RL linear robot machine (see Fig. 2). “As each pallet is presented to the machine,” says Härle, “rows of parts are unloaded and placed in a linear fashion onto a conveyor belt . This depalletizing process results in one row being placed on the conveyor approximately every eight seconds. Every 2 s the conveyor is forwarded one part. However, because the manufacturer required a throughput of 120,000 parts per day, four separate conveyors were loaded in parallel from the same depalletizing machine. This results in a throughput of approximately one part every 0.5 s.”

System control

Härle and his colleagues developed two user interfaces that run on two standard industrial PCs under Windows XP. The PCs are connected via a real-time Ethernet interface. To ensure real-time communication with a programmable logic controller (PLC), the PCs run Beckhoff’s TwinCAT Soft-SPS software.

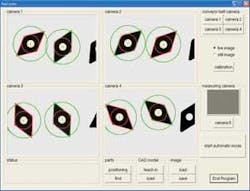

The first interface was developed in Visual Basic and provides system-level control for the PLC. This interface allows the operator to view all the current jobs being processed by the system, add further jobs to the queue, and monitor the layout and settings of specific jobs. The master PC runs a Microsoft Access database that, in addition, allows managing different part specifications and storing measurement results. The second interface, developed in Visual C++, runs on the host PC and allows the user to view live images as they are captured from the multiple camera systems deployed on the production line (see Fig. 3). Using this interface, the operator can also calibrate the system, interactively train new shapes from training images, and monitor the measurement results.

Machine vision

The inserts are placed on all four conveyor belts approximately 20 mm apart (depending on the number of rows of the trays) by the depalletizer and then moved under a machine-vision system, where they are inspected for position, rotation, and geometric properties such as in circle, outer circle, hole diameter, and included angle. As the parts move under the station, they are backlit so that the system can more easily determine their orientation.

To digitize images of the parts, several CS8420 monochrome CCD cameras from Toshiba Teli are interfaced to a PC using an Eagle frame grabber from Imaging Development Systems. “Because four inspection stations are required,” says Härle, “the system uses four cameras that are connected to one frame grabber that digitizes images into the RAM of the PC (see Fig. 4).

The images are analyzed with the HALCON machine-vision library from MVTec Software. “Using the pattern-matching tool within HALCON,” says Christoph Hansen, application engineer at MVTec, “the position and orientation of each part can be extracted from the image, even if parts are rotated or partly occluded. The software uses HALCON’s contour-based pattern-matching and locates objects based on their shape. This leads to reliable detection even under changing lighting conditions.”

For standard shapes, the internally used shape models are generated with a CAD description; for special shapes the internal model is created from a training image. In both cases, the models are adapted to the different views of the four inspection cameras using the information obtained during camera calibration. Dimensions such as in circle, outer circle, and hole diameter of each part are measured with a precision of 50 µm.

“When measuring the cutting-edge radius and the part angle, subpixel-accurate edge-extraction algorithms are used. These procedures also work reliably under rough production conditions. That is only possible with the highly sophisticated algorithms offered by HALCON,” Härle explains. “With HALCON, we also have been able to integrate further functionalities into the machine,” he adds. “The system checks if a part is visible in the camera, detects wrong parts, and can measure the dirt on the conveyor belt. These service functions are very useful to the operator.”

Once the dimensions have been calculated, they are compared with the dimensional limits and tolerances of known good parts from an ISO-standard database. In this way, the system determines whether the parts can be transferred to the next inspection station or have to be discharged.

After the software has determined both the x-y position and orientation of the indexable inserts, the coordinates of each part are transmitted from the PC to a programmable logic controller. With the help of HALCON´s 3-D camera calibration, the system establishes a relationship between each pixel and the robot coordinates. The determined position and orientation data can be handed over directly to the robot. Tilt of the camera, distortions of the lens, as well as not-right-angled robot coordinates are corrected. The height of the indexable insert is also considered during measurement.

The PLC drives an RL load robot that individually unloads the parts in proper orientation to a chain belt conveyor. Depending on the shape and dimension of the insert, its position and orientation on the chain belt conveyor, as well as in the vending boxes, are calculated automatically. “To increase throughput,” says Härle, “four good parts from all four conveyors are then placed onto one plate mounted on the chain belt conveyor. To handle the enormous range of approximately 10,000 different inserts, only three different grippers are necessary. To reduce the changing time between following jobs, the grippers can be changed automatically by the system.” On the conveyor, the inserts are magnetized so that as parts are transferred from the conveyor, they are placed and held in a known fixed position.

Telecentric setup

After the parts have been placed on the chain-belt conveyor, they are moved under a second inspection station (see Fig. 5). Here, the parts are imaged by another Toshiba Teli CS8420 CCD camera that is fitted with a telecentric lens from Sill Optics. The images from the camera are captured by a second Eagle frame grabber that is also integrated into the host PC. Says Härle, “To properly inspect the radius of the cutting edge of the parts requires detection with 10-µm accuracy.”

In the second inspection station a telecentric setup is used because of the problems that arise from the inherent projection properties of conventional lenses. “Perspective distortions can create significant interpretation problems when captured images need to be analyzed automatically,” says Härle. “With the telecentric setup and the subpixel-precise edge extraction that is possible with HALCON, the borderline of the parts can be extracted and measured with high accuracy.”

Known good parts are transferred to a laser marking system-an Electrox YAK Cobra-where a short string of ASCII data is inscribed onto each part. “These data,” says Härle, “describe coating materials such as titanium nitride that are used to coat the indexable inserts with a hard and wear-resistant surface.”

After inscribing the data, parts are transferred to a packaging system where they are placed in boxes, labeled, and shipped to the customer. To do this, the four indexable inserts are transferred from the mechanical conveyor to the vending boxes using another four RL robot pick-and-place systems.

Pack and ship

To pack the boxes automatically requires another multistation system. Empty boxes are removed from a carousel and transferred to a conveyor belt. A gantry robot then transfers these empty boxes from the conveyor belt to the filling station. Parts placed in these boxes then pass through a demagnetization station, and the boxes are closed and printed labels applied to them. The finished packed boxes are transferred from the conveyor belt to another carousel where they are off-loaded for shipping.

In the future, ROBOWORKER plans to provide additional functionality. According to Härle, this will include deploying an analysis system for detecting small breakouts in the object’s contour with sizes down to 10 µm.

Company Info

Beckhoff

Verl, Germany

www.beckhoff.com

Electrox

UK

www.electrox.com

Imaging Development Systems

Obersulm, Germany

www.ids-imaging.de

MVTec Software

Munich, Germany

www.mvtec.com

ROBOWORKER Automation

Weingarten, Germany

www.roboworker.com

Sill Optics

Wendelstein, Germany

www.silloptics.de

Toshiba Teli

Tokyo, Japan

www.toshiba-teli.co.jp