Snapshots

System ensures device traceability

Central Labo Europe (Paris, France; www.central-labo-europe.com) specializes in manufacturing plastic medical devices and must ensure the traceability of biological samples stored in plastic containers. Each container holds 48 separate wells destined to contain samples of blood or serum. In the past, each container was identified with a barcode. If one problem sample was found, the entire container had to be rejected. To make it possible to identify and track individual sample wells, Central Labo turned to Technifor (Miribel, France; www.technifor.com), a supplier of marking and verification products and services.

Technifor installed a laser-based direct-part-marking (DPM) system capable of dealing with the surfaces of the individual wells and providing complete traceability. The DPM system needed to mark two different codes with a result that would be both machine-legible and visible to the human eye. The system had to use a completely automated process complying with Class 10000 clean-room conditions, maintain zero risk of error, and ensure any nonconforming pieces are rejected during the process, while meeting production requirements of one piece per minute.

Each of the 48 wells in the container is marked with the container code, as well as its own unique identification code in text. A Data Matrix code contains the same information. A Cognex (Natick, MA, USA; www.cognex.com) In-Sight 1010 camera inspects and verifies that each code can be decoded. The positioning of the vials is verified by the vision system and relayed to a computer.

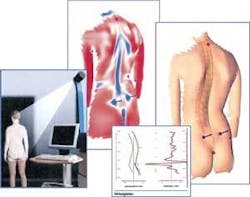

Vision tackles back pain

Back pain is so widespread that it is the most common cause of work disability and early retirement, with patients getting younger and younger. Children are now diagnosed with postural deformity, tilted pelvis, scoliosis, or kyphosis at preschool age. To help physicians find the exact cause of the pain and prescribe effective therapies, Diers International (Schlangenbad, Germany; www.diers.de) has developed the 3- or 4-D “formetric” method, which measures the spine by taking a stereographic image of the back. First developed in cooperation with several universities and the European Union, the original goal was to build a radiation-free biomechanical measuring method that would spare children with scoliosis from frequent x-ray exposure.

A grid is projected on the patient’s back with a light beam and scanned with a camera. From the image, the system calculates anatomical landmarks such as the seventh cervical vertebra or the “pelvic dimples” and derives the spine posture from these data at an accuracy of one- to two-tenths millimeter. During the measurement, the patient stands in an upright position about 2 m from the height-adjustable scanner. The image-acquisition time of 40 ms accommodates the fact that children, in particular, never stand absolutely still. Diers uses the uEye series UI-1540-M USB 2.0 camera from IDS Imaging Development Systems (Obersulm, Germany; www.ids-imaging.com), which can obtain high-resolution images for dynamic measurements such as on a treadmill--an activity that requires a capture rate of 10 frames/s.