Real-time operating system sorts mail fast

Real-time operating system sorts mail fast

Every business day, the United States Postal Service (USPS) processes millions of pieces of mail at more than 250 major facilities nationwide. Given ever-increasing volumes of mail, the USPS work force of more than 600,000 depends heavily on machinery to help process mail quickly and efficiently. One such machine, the Delivery Bar Code Sorter (DBCS), can sort 35,000 to 40,000 letters per hour.

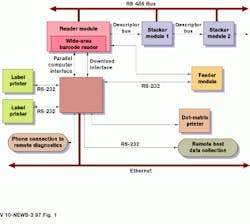

Designed by ElectroCom Automation (ECA; Arlington, TX) in partnership with AEG ElectroCom (Konstanz, Germany), the DBCS sorts mail pieces bearing the POSTNET barcode. Two major components make up the DBCS--a PC running the QNX operating system from QNX (Kanata, Ont., Canada) and a sorting machine. While the PC controls the machine and user interface, report generation, and diagnostics support, the DBCS consists of feeder, reader, and stacker modules controlled by embedded processors that direct mail pieces to their destination.

In operation, letters are fed into the feeder and moved through the reader and stacker by roller-driven belts. The reader module scans the barcode and transmits information to the PC to determine the destination pocket for the mail. The reader module then diverts the mail piece and sends a tracking message to the first stacker module. Mail pieces are then transported through the stacker modules and diverted into their destination pockets.

Several adapter boards are used in the PC to interface with different modules in the system. A custom board provides the parallel computer interface with the reader module. Zip-code and pocket assignment data are exchanged using this interface. A second custom adapter board provides a 10-Mbit/s serial link from the PC to the barcode reader that is used for downloading control code at startup and for performing barcode reader diagnostics. To communicate with the feeder module, thermal label printers, and a separate data collection computer that stores zip-code information for mail pieces, the system uses the DFlex-8 serial I/O board from Connect Tech (Guelph, Ont., Canada). For TCP/IP-based file transfers to and from a central file server, the PC also includes an WD8003 series Ethernet interface board from SMC (Hauppauge, NY).

To route trays of mail through the mail-processing facility, operators batch print routing labels using two M-410EC thermal label printers from Microcom (Westerville, Ohio). Once printed, each label is attached to a tray of sorted mail. Mail personnel with hand scanners then use these labels to further direct the trays of mail.

The DBCS is a network of processors with several different communication interfaces. The reader module serves as master of an RS-485 network with the stacker modules as slaves. All message traffic between the PC and the reader or stacker modules passes through a proprietary, parallel computer interface. The reader module forwards PC-to-stacker and stacker-to-PC messages via this interface and the RS-485 network. The PC also communicates with the feeder module via an RS-232 connection.