Snapshots

System verifies connector assemblies

Dial-X Automated Equipment (Albion, IN, USA; www.dial-x.com) provides single-source machine-building and integration services for pharmaceutical, food and beverage, automotive, and consumer goods manufacturing applications. To develop a connector assembly verification system based on machine vision, Dial-X assembled and tested all equipment in-house, installing the equipment at the customer’s plant, and providing product support throughout the machine’s lifecycle.

For the connector inspection system, Dial-X used 11 PresencePLUS cameras from Banner Engineering (Minneapolis, MN, USA; www.bannerengineering.com), along with two spotlights, a backlight, and an on-axis light. Each lighting type was selected for the machine depending on the connector part to be inspected. The components were sold to Dial-X by C&E Sales (Dayton, OH, USA; www.cesales.com), a provider of automation solutions. “If we’re verifying the connector’s shape, we’ll use a backlight to create a silhouette of the product,” says Ryan Berkes, Dial-X project manager. “For verifying color, we’ll use a spotlight to highlight the front part of the connector. The on-axis light is used to mute the color of one of four internal connector parts. This allows us to measure and verify that two parts are assembled correctly.”

Bioengineers develop microfluidic microscope

Researchers at the California Institute of Technology (Caltech; Pasadena, CA, USA; www.caltech.edu) have developed a very compact, high-resolution microscope that operates without lenses but has the magnifying power of a high-end optical microscope. It can be used in the field to analyze blood samples for malaria or check water supplies for giardia and other pathogens, and could be mass-produced for around $10.

“The whole thing is truly compact—it could be put in a cell phone—and it can use just sunlight for illumination, which makes it very appealing for Third World applications,” says Changhuei Yang, assistant professor of electrical engineering and bioengineering at Caltech, who developed the device along with colleagues.

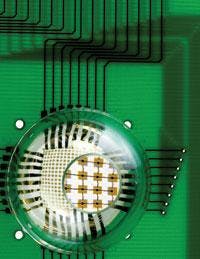

The instrument combines traditional semiconductor technology with microfluidics—the channeling of fluid flow at small scales. A layer of metal is coated onto a grid of a CCD sensor and a line of holes less than 1 μm in diameter and 5 μm apart is punched into the metal. Each hole corresponds to one pixel on the sensor array. A microfluidic channel is added on top of the metal and sensor array.

As cells or small organisms cross over the holes, the objects block the passage of light onto the sensor, which produces a series of dark and light images. Because the holes are slightly skewed the images overlap slightly; they are stitched together to create a 2-D picture of the object. Yang says that eventually the microscope could be incorporated into devices implanted into the human body to autonomously screen for and isolate, for example, rogue cancer cells in blood circulation.

Laser-based system sorts vegetables

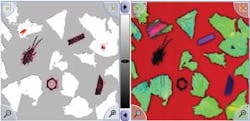

The Raptor Laser line from Key Technology (Walla Walla, WA, USA; www.key.net) now includes a combination of lasers and color cameras designed to inspect vegetables by using more than one wavelength simultaneously, which increases flexibility and the ability to detect foreign material and product defects in processed and fresh-cut vegetables. For example, the new system enables leafy green producers to run baby spinach in the morning and iceberg in the afternoon on the same line. Difficult sorts such as discriminating between undesirable romaine core and desirable romaine rib are made easier.

The system sorts based on differences in the structural properties of the objects and differing levels of chlorophyll, as well as color, size, and shape. Improving the differentiation between good product and unacceptable objects maximizes product quality and food safety while minimizing yield loss. The company’s KeyWare software is tailored for each application and selects the most pertinent data for the product being sorted to optimize the image processing algorithms.

Hemispherical eye stretches vision

Researchers at the University of Illinois/Urbana-Champaign (www.uiuc.edu) and Northwestern University (Evanston, IL, USA; www.northwestern.edu) have created a hemispherical camera using an array of single-crystalline silicon detectors and electronics in a stretchable, interconnected mesh—an advance that they say may improve camera designs and enable bionic eyes. “Conformally wrapping surfaces with stretchable sheets of optoelectronics provides a practical route for integrating well-developed planar device technologies onto complex curvilinear objects,” said John Rogers, professor of materials science and engineering at Illinois. The work is described in the Aug. 7, 2008 issue of the journal Nature.