FireWire components eliminate multiple buses

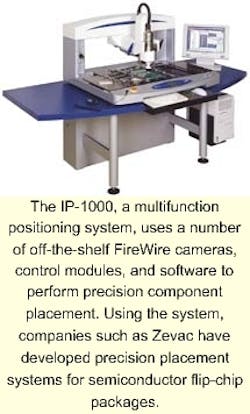

Cellular telecommunication systems and portable devices often require the use of flip-chip packages to conserve space on printed-circuit boards (PCBs). To meet the high-precision manufacturing needs required to perform precise positioning and placement of these components, a number of companies offer robot-controlled four-axis-positioning systems. One company, Zevac (Solothurn, Switzerland), has designed its Onyx 32 semiconductor-placement system based around the IP-1000 multifunctional positional system originally developed by Infotech Automation (also Solothurn).

In operation, the Onyx automatically picks, inspects, and places flip-chip packages on PCBs. After being picked by a pneumatic force sensor, the flip-chip packages are inspected by an upward facing CCD camera situated to the right of the robot machine. Once each part is inspected, another CCD camera guides the robot head to position the component onto the PCB at 1.5-µm resolution of. To attain this level of accuracy, Infotech used several off-the-shelf FireWire-based imaging, motor control subsystems, precision linear drives, and rotary encoders.

"Instead of using a bulky wiring harness to carry data, input/output, and power signals around the system," says Robert Black, chairman of Infotech's sister company Meta Controls (Morrisville, NC), "the IP-1000 system uses a single IEEE-1394a (or FireWire) cable." To image the flip-chip package before placement, a FireView-1 CCD-based digital camera from MetaControls is used to capture 640 x 480 x 24-bit images. These images are then transferred to the host over the FireWire bus using PC-resident Visual Machines software from Infotech.

Because Visual Ma- chines is an object-oriented, modular software environment, it can be extended to include machine-vision measurement and control using the Common Vision Blox Active X tool library from Integral Vision (Farmington Hills, MI). Using this package, images of solder bumps on the flip-chip packages are analyzed before being placed on the PCB.

"Rather than create a new bus structure for I/O and motor control," says Black, "the design of the IP-1000 system uses the same FireWire interface to control the servos and rotary encoders." To accurately position each flip-chip on the circuit board, the robotic head of the IP-1000 moves under control of Meta Controls' FireWire-based FireBlox control modules that are also controlled by Visual Machines software. These FireBlox control modules can power two 200-W brushless motors, drive or read 16 devices, and sense eight analog variables simultaneously.

To control the linear and rotary (x, y, z, and q motion of the head of the IP-1000, the motor controllers interface to rotary and linear encoders from Heidenhain (Schaumburg, IL) that, in turn, control linear servo motors from Etel (Môtiers, Switzerland). To configure these motors with the FireBlox controllers, Meta Controls BloxView graphical control software is used. Like the company's Visual Machines software, the Active X-based BloxView allows developers to extend its capability using tools from Microsoft's Visual Studio or other automation systems such as LabVIEW from National Instruments (Austin, TX).

"The design of the IP-1000 demonstrates the capability of FireWire as an good alternative for both machine vision and control," says Black. "Using an open object-oriented software approach allows both vision and I/O to be performed with one common user interface," he adds. Introduced at the recent International Robots & Vision show (Chicago, IL; June 2001), the IP-1000 is now available as an OEM product from Infotech. For systems developers wishing to design similar systems, Meta Controls is also offering the FireWire-based FireView-1 camera, FireBlox-1 control modules, and BloxView control software as OEM components.