FireWire cameras simplify integration

Robotic platform contains distributed processing and signal and power nodes.

By C. G. Masi, Contributing Editor

Air-Vac Engineering Company (Seymour, CT, USA) manufactures work cells used by electronics manufacturers to modify and repair printed-circuit boards populated with surface-mount-technology components. Air-Vac engineers decided that, to solve operator-related problems, their next generation of desoldering and repair systems had to be fully automated, including integrating a vision system.

The first step, creating the tools needed to manipulate materials and components with microscopic precision, had been done: a desoldering tool reaches down, heats a device to be removed, and picks it off the board (see Fig. 1). Making these tools work as part of an automated system, however, was a major challenge.

The controls for their first systems consisted of motherboards with multiple cards plugged into them to control the various tools. Each of these cards required a different software driver. Typically, cards came from a variety of suppliers, creating problems in terms of maintenance and in maintaining inventory levels.

Air-Vac turned to motion-control supplier Adept Technology. Adept engineers had already used FireWire technology to build an architecture for distributed motion control and integrated vision controls called SmartServo. "We found that we could actually package the servo-control capability and power electronics into a small physical unit that we could locate right next to the motor," Keith Bailey, director of the Adept OEM Business Unit, says. "All the cabling that we normally had to run from the motor back to the control cabinet could be eliminated. That meant that we could close the entire servo loop right at the motor. Motor-power leads, instead of being 10 feet long, now are eight inches long, and the encoder feedback cables also have become very short. Limit switches tie directly into an electronics package located right at the motor."

FireWire (IEEE 1394) is a communications-network protocol originally developed by Apple Computer as an alternative means for connecting fast peripheral devices to personal computers without having to install expansion boards. It does a job similar to USB, but with much higher bandwidth. FireWire is typically associated with systems that capture full-resolution images at video rates, although it can provide high-speed serial communication with any conforming peripheral device.

Real application

Air-Vac applied Adept's technology to its Onyx32XL fully automated system for extra-large electronic assembly and repair (see Fig. 2). "The benefit in our particular platform is that we reduced by 70% the amount of wiring that was internal to the machine," says Brett Lasto, Air-Vac director for new products.

The finished machine contains no bulky equipment cabinet connected to the system (see Fig. 3). The intelligence needed to run the peripheral devices resides in the FireWire network nodes. All of the information exchange between system elements goes over the six-conductor FireWire communications link. The standard's daisy-chain interconnection scheme further reduces the number of cable runs.

A second major advantage is the architecture's flexibility. "We have always had camera systems on our machines," Lasto says. "On our automated platform, we were sure we would have two cameras, but we also potentially could have more."

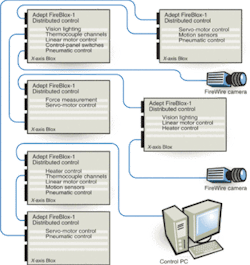

When making its complete vision-guided motion-control solution, Adept developed FireBlox modules, which provide an interface between the network and dumb peripherals. Each module is a small package about the size of a deck of cards that has amplifiers, power electronics, digital and analog I/O, and the servo controls to run two closed-loop control channels all in one module (see Fig. 4). They run in an open-architecture environment so integrators can develop their software environment in Visual BASIC or C.

For the SMT-board-repair station, Air-Vac used FireBlox modules to control other functional capabilities, such as heaters and suction tools, in addition to the motion-control capabilities. The company used the analog and digital I/O ports on the FireBlox modules to control the SMT repair tools and Adept's vision-guided navigation system to bring the tools to the right place at the right time.

"We looked at lots of different digital networks, including SERCOS, Profibus, DeviceNet, Ethernet, and CANbus," Adept's Bailey recalls. "We found that, for our applications, FireWire really fit the bill very well."

One of the primary features that attracted Adept to FireWire is the fact that devices are being manufactured in volume because of adoption in consumer electronics. Such acceptance means that the chip sets become available at reasonable cost, and cables become commodity items. "You can buy FireWire cables in Wal-Mart, for example," Bailey points out.

One of the advantages of using FireWire is the wide variety of image sensors available. For the Onyx32XL, Air-Vac chose the DFWV500 camera manufactured by Sony Electronics of America . This camera incorporates a 1/3-in. progressive-scan CCD along with the IEEE 1394-1995 interface. It carries a Zoom 70XL C-mount lens manufactured by Thales-Optem The lens' 7:1 zoom ratio provides magnifications from 0.75 to 5.25 and numerical apertures of 0.024 to 0.08.

"An industrial PC generally has a large backplane with 14 slots, one of them being used for the processor," Lasto says. "To make them robust, vendors sell them with a double fan, over-temperature sensors, and noise immunity." When using distributed FireWire architecture, all of that special construction is unnecessary. You do not need the noise immunity, the over-temperature sensors, or the double fans. A simple computer that has the FireWire connectors built into it is sufficient.

"The robotic platform that we offer now could not be manufactured without distributed processing and nodes that contain signal and power," Lasto points out. "We have nodes right out in the robot's head where there's no room for anything except the six-wire FireWire cable. So we believe that the mechanics behind our robotic platform could not be possible without these Adept FireWire-based controllers."

Company Info

Adept Technology, Livermore, CA, USA, www.adept.com

Air-Vac Engineering Company, Seymour, CT, USA, www.air-vac-eng.com

Apple Computer, Cupertino, CA, USA, www.apple.com

Institute of Electrical and Electronics Engineers, www.ieee.org

Sony Electronics of America, Park Ridge, NJ, USA, www.sony.com

Thales-Optem, Fairport, NY, USA, www.thales-optem.com

1394 Trade Association, www.1394ta.org