Raw or inadequately prepared seafood may contain parasites such as anisakid nematode larvae. Human consumption of live parasites poses health risks, but machine vision can help by determining if a parasite is alive or dead. However, just observing a larvae’s state of motion does not represent a reliable indication of nematode larvae infection, as these can temporarily fall into a non-moving state. Conclusive determinations involve characterizing viability, which technet (Stuttgart, Germany; www.technet-gmbh.com) addresses with its Viability Test Device (VTD). The VTD was developed as part of the EU-project Parasite as a preliminary step for use in food control laboratories (parasite-project.eu/outcomes)

More than six million tons of fish processed for human consumption each year in Europe must be manually or automatically inspected for potential health risks such as anisakiasis, a human parasitic infection of the gastrointestinal tract. Assessment of viability by measuring the reproduction rate – a standard microbiology method– is not applicable for marine parasites like Anisakis nematodes. In this study, viability is based on evaluating the larvae’s state of curvature energy independent from motion, followed by a classification as a living or dead state, with the latter representing no risk to humans.

For image capture, the VTD uses a UI-3370CP-NIR-GL Rev.2 USB3 camera from IDS Imaging Development Systems (Obersulm, Germany; www.ids-imaging.com). This camera features a 4 MPixel monochrome near infrared (NIR) CMV4000 CMOS sensor from ams (Formerly CMOSIS; Premstaetten, Austria; www.ams.com). In addition to the camera, the system features a non-telecentric MeVis-C lens (Qioptiq/Stemmer; Puchheim, Germany; www.stemmer-imaging.com) equipped with a narrow bandpass filter (AHF Analysentechnik; Tübingen, Germany (www.ahf.de) and a pulse-width modulated LED NIR-illumination system (Planistar; Himmelstadt, Germany; www.planistar.de). Heurisko image analysis software modules (AEON, Hanau, Germany; www.aeon.de/en) are integrated into the software developed by technet for the VTD.

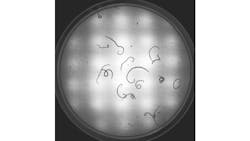

Placed vertically above a petri dish into which an operator places samples, the camera captures series of images in the NIR range (835 to 865 nm) at 2 fps and the 3D shape of the larvae is reconstructed in the software from the measured 2D contour data. The VTD models parasites as elastic, cylindrical systems. Assuming a link of living nematode’s metabolism and its inner pressure, the shape is used as an indicator for viability.

The VTD determines the normal vectors for 3D model parasites and determines the associated elastic curvature energies—whose correlation with data from the visual inspection has proven to be valid in experiments. The interaction between curvatures, contraction of longitudinal muscles, and inner pressure then helps make a viability determination, which helps to ultimately classify larvae as living or dead and help prevent consumers from getting sick. Camera, temperature, illumination, position and time data are written into each frame, ensuring a high level of traceability of the test results, according to technet.

Before imaging biological samples, reference images are generated from empty petri dishes. Images for viability tests are calibrated by radiometric two-point calibration based on the generated references images. To check the VTD, 250 mm thick ETFE (Ethylene tetrafluoroethylene) films printed with standard patterns are positioned in petri dishes. In the NIR wavelength, the films are 95% translucent, and the different printed areas reflect light from 100% to 50%. With these patterns, artificial curvature data and viability states are simulated. Deviations from known target data indicate potential system faults such as radiation behavior of the NIR-LEDS.

IDS’ camera was chosen for the system, according to technet, because its large pixels provide low-noise and high sensitivity to light, along with a pipelining feature that allows further exposure while the sensor data reads out, which speeds up the readout and effectively reduces motion blur. The uEye CP camera delivers images from the petri dish with high information density and minimal information loss through unused image area and provides the necessary data quickly and with high quality, explains Michael Kroeger, physicist at technet.

Initially developed as part of a research project, technet’s VTD is now available for the fish industry, research institutes, and sanitary authorities.

About the Author

James Carroll

Former VSD Editor James Carroll joined the team 2013. Carroll covered machine vision and imaging from numerous angles, including application stories, industry news, market updates, and new products. In addition to writing and editing articles, Carroll managed the Innovators Awards program and webcasts.