Seeing Through the Cracks

Project summary

Solar power is a clean and attractive alternative source of electricity. There has been an increasing demand for photovoltaic modules to be cheaper and become more efficient at solar energy conversion. Solar cells, which form the basis of a solar power system, consist prevalently of crystalline silicon. In crystalline silicon devices, cell breakages resulting from micro-cracks, degradation and shunted areas on cells are proven to cause major problems and remarkably affect module performance. Structural defects such as these may stem from challenges in silicon processing, the quality of crystalline lattices or other external influences. To address these issues, an array of photo-emissive diagnostic and quality control tools, based around camera detection systems, has rapidly developed over the recent years.

DISSEM, Allied Vision’s partner in Korea, helped leading providers of solar cell inspection systems develop a cost-efficient imaging solution based on electroluminescence in the near-infrared spectrum.

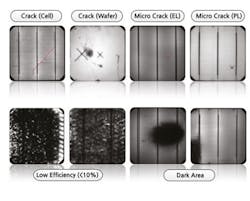

Many defects cannot be visually observed with the conventional imaging system. One way to detect all these problems that may affect module performance is by a measurement method known as the Electroluminescence Imaging (EL). EL imaging is a powerful quality assessment tool for both crystalline and thin film solar modules. It consists of applying a direct current to the solar module and measuring the photoemission by means of an infrared-sensitive camera. When properly adjusted and configured, the system is able to accurately detect numerous failures and ageing effects in very short times. The amount of light a cell generates for a given applied current can also serve as a measure of the solar cell’s conversion efficiency.

Challenges of defect detection in photovoltaic modules

- As photovoltaic electroluminescence emissions are very weak, extremely sensitive cameras are required.

- A good software that can study the image for dark defects, uniformity and overall efficiency of the cell is needed.

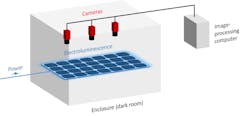

An electroluminescence system utilizes multiple cameras in an enclosure free from ambient light. Placing the solar cell inside this enclosure, the system is linked to a constant current source. The cameras capture an image while the current passes into the cell. With the assistance of a reliable inspection software, this image will then be studied for dark defects, uniformity, and overall efficiency of the cell. Based on the severity of the defects, the cell will either be accepted or rejected.

Photovoltaic module inspection is a challenging process that needs a camera capable of snapping clear images at a specific wavelength range of 950-1250nm. As photovoltaic electroluminescence emissions are very weak, extremely sensitive cameras are required. The camera must have the ability to precisely render the whole panel in a single snap and an adequate resolution that enables easy detection of broken contacts, different light intensities, micro-cracks, and uniformities of the emitted photons to electrons that would otherwise not be possible by a visual inspection.

Photovoltaic Module In-Line Inspection

Solutions delivered by Allied Vision

- A high quality camera that has very good sensitivity in the required range

- Favourable price compared to other competitors‘ CCD cameras

- A convenient, compatible and easy to use software for fast configuration

The Manta G-145B Near-Infrared (NIR) is designed to offer good responsivity in the NIR region, delivering 20~30% QE at 900nm. Equipped with a charge-coupled device (CCD) image sensor, the Manta G-145B NIR camera is well suited for industrial and inline solar cell quality control processes. CCD, being a two-dimensional array sensor, is an excellent tool for high-throughput testing of individual photovoltaic cells and large panels due to their high Quantum Efficiency (QE), low read noise and down to sub-second frame read out.

Compared to other NIR products in the market, customers felt that Manta G-145B has a high sensitivity to harness induced EL from solar modules, using weak emissions in the NIR to detect shunts, crystalline defects and broken finger electrodes before and after the lamination process. The favourable and affordable price of the Manta camera compared to other CCD cameras of similar profile was also a key factor in customers choosing this camera for their PV Module Inspection System. Lastly, the VIMBA Software Development Kit (SDK) provided by Allied Vision is intuitive and simple to use, making it efficient and convenient during the whole set-up.

For particularly demanding photovoltaic inspection applications, Allied Vision’s Goldeye camera series offer a more advanced solution. Goldeye is a short-wave infrared camera with a maximal sensitivity between 900 and 1,700 nm, which makes it an ideal solution to detect weaker electroluminescent radiations at higher wavelengths than the Manta NIR.