Smart vans with inspect state roadways

Smart vans with inspect state roadways

By Lawrence H. Brown, Contributing Editor

Checking, maintaining, and repairing roadways requires accurate data collection. In the past, collecting such roadway data required expensive, labor-intensive, time-consuming visual inspections. These inspections tended to be involved and prone to human errors, making them inconsistent. To solve this problem, the Connecticut Department of Transportation (DoT; Rocky Hill, CT) started photologging its roadways to create an integrated system of video images and data for storage and retrieval (see "Integrated office retrieval saves time and resources," p. 20.)

"We began experimenting in 1971 by photographing selected roadways

with a video camera," explains John Hudson, DoT photolog supervisor.

Unfortunately, changing technologies and strict state budgets forced the Connecticut DoT to keep changing its roadway imaging systems. Then, two years ago, the state contracted with Roadware (Paris, Ont., Canada) to design a modular Automatic Road Analysis (ARAN) system. Today, Connecticut`s DoT uses two ARAN systems to assess the condition of 12,550 km of roads and 1280 km of access and exit ramps throughout the state each year.

Integrated systems

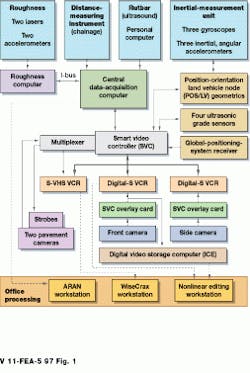

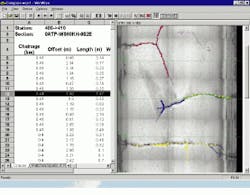

In operation, the automated visual inspection system measures a road`s slope, roughness, and pavement characteristics while simultaneously providing a video log of the roadway. Installed in a converted Ford van, the system is outfitted with front- and side-view digital video cameras and laser and ultrasound subsystems, all controlled by five on-board computers (see Fig. 1). The collected data are used to qualify and quantify pavement, roadside, and bridge conditions.

Because the system uses multiple sensors, the collected visual, ultrasound, and laser-based data must be correlated using both local and global reference positioning systems. To tag data by mileage, the ARAN system incorporates a distance-measurement instrument from Encoder Products of Canada (Toronto, Ont., Canada). The instrument consists of a plate fitted on the hub of the van`s left rear wheel. Spaced circularly around the edge of the plate are 1800 tiny windows. Located on either side of the plate, a light-emitting diode (LED) sends light pulses to an accompanying photodetector, which counts the pulses as the van travels along the roadways. The light data are then digitized and delivered to a central data-acquisition computer, located in the back of the van. Here, software is used to determine the distance traveled by the van.

All the data and images collected by the ARAN system are referenced to longitude, latitude, and elevation parameters. This is accomplished by integrating data information from a global positioning system (GPS) into the central data-acquisition computer.

Using off-the-shelf antennae and receivers from Leica (Torrance, CA), as many as 12 GPS satellites can be referenced to provide accurate positioning information. These local and global references tag the position of the van to the visual, ultrasound, and laser-based data collected by the inspection system. Such references also provide a rapid means of finding images and data during replays.

Data inputs

To capture images of the roadways and surrounding area, two Sony DX9000 cameras are positioned at the front and side of the van (see Fig. 2). In operation, red-green-blue (RGB) images from the cameras are delivered to a Sony digital recorder. Linked via an RS232 interface to the central data-acquisition computer, the front-view camera is triggered to capture a frame every 0.01 km. In this manner, the road-analysis system minimizes the number of captured frames and related storage requirements.

Simultaneously, the front-view camera records continuously at 30 frames per second (frames/s), resulting in more than 100 standard frames/km that are included in the final editing process when additional information for a given area is needed. The side-view camera records only at 30 frames/s. Stored on video-tape recorders, the camera data are converted from RGB to YUV format by a transcoder board from Nova Systems (Canton, CT) installed in the smart video controller.

To detect ruts in the road, the front of the van is equipped with a horizontal bar, known as a rutbar, that holds 19 ultrasonic transducers. By measuring the reflected ultrasound profile of the roadway from these transducers, the inspection system can detect ruts as small as 100 mm. An additional 37 sensors mounted on two telescoping wings of the rutbar enable 12-foot-wide coverage of the roadway. All the sensor data are then pro cessed by a single-board computer from Ampro (Sunnyvale, CA), lo cated in the rutbar housing. As well as digitizing the signals, this computer system also determines rut depths, which are then transmitted and displayed in real time on a van monitor (see Fig. 3).

To determine the roughness of the road, the ARAN system uses a machine-vision system located at the back of the van. To image cracks, the road is illuminated with strobe lighting devices from EG&G Optoelectronics (Salem, MA) to ensure that the reflected light from other objects is eliminated. Programmed by the central data-acquisition computer, the strobe lights are synchronized with two progressive-scan digital cameras from Pulnix (Sunnyvale, CA).

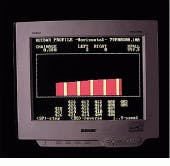

After capture, the road images are analyzed on-board by a PC-based package called WiseCrax from Roadware. "Because WiseCrax uses a gray-scale-based analysis, a consistent illumination field is necessary to offset any stray effects," explains Steve McKenna, Roadware vice president of research and development.

The WiseCrax software helps measure the type (such as edge, transverse, or faulting), severity, and extent of pavement cracks. Left and right images, each two feet wide and 12 feet long, are seamlessly joined to provide a lane-width view of the road. According to McKenna, cracks as small as 0.10 inch wide (3 mm) can be detected by the inspection system (see Fig. 4).

Integrated replay

Final editing of the video tapes from the Sony digital recorder is performed on a nonlinear editor, PC-based workstation. This workstation contains a digital-signal processing (DSP) board from Digital Processing Systems (Markham, Ont., Canada) for nonlinear editing, and SpeedRazor editing software from In-Sync (Bethesda, MD). After conversion and editing, the frames are written in NTSC format to a laser-disk jukebox storage system that contains six 9-Gbyte hard drives. In the jukebox, double-sided, 12-in. laser disks are used to store 108,000 images.

Front- and side-view images total about 1.875 million each. The access and ramp images number approximately 100,000. All the images fill some 18 laser disks a year. These images can be accessed by laser-disk players at retrieval stations located throughout the state.

Expanding uses

Although other states such as Massachusetts and South Dakota are using a version of the ARAN system, none has been as aggressive in adapting, deploying, and marketing roadway imaging capabilities as Connecticut. During the past year, the number of retrieval stations available throughout the state has been doubled. The DoT plans to continue that expansion as the demand for use of its photologging system continues to grow.

The US Federal Highway Administration owns seven ARAN systems that are being used to monitor the interstate highway system. By combining the capabilities of both the federal and state photologging systems, a nationwide monitoring system could provide valuable roadway information for planning, maintaining, and repairing highways.

FIGURE 1. The Automatic Road Analyzer (ARAN) field-image/data-acquisition inspection system is used by the Connecticut Department of Transportation to assess the physical condition of state roads. The integrated system, which is installed in van-type vehicles (below), is equipped with lasers, accelerometers, gyroscopes, computers and computer boards, sensors, cameras, controllers, videocassette recorders, and graphics cards. As the van is driven on the state roadways, the inspection system automatically maps and photologs imaging, positioning, and video data for workstation processing and analysis.

FIGURE 2. The ARAN roadway inspection system occupies the entire rear panel of a van-type vehicle. The two small monitors (center, top) display road roughness images, right and left side, respectively, for a full lane-width view. The large, multifunctional monitor (center, middle) shows front and side camera images, histograms for rutbar measurements, and menu and input screens.

FIGURE 3. To detect ruts in the roadways, the front of a Ford van is equipped with a horizontal bar called a rutbar. This bar contains ultrasonic transducers, a single-board computer, and special software that produces a reflected ultrasound profile of the roadways that is displayed on a monitor inside the van. Sonograms are used to detect and measure the roadway ruts. The top sonogram shows a smooth roadway; the bottom sonogram indicates two ruts.

Company Information

Ampro Computers Inc.

San Jose, CA 95138

(800) 966-5200

Fax: (408) 360-0222

Web: www.ampro.com

Applied Analytics

Markham, Ontario, L3R 6A8 Canada

(905) 475-2221

Connecticut Department of Transportation

Bureau of Engineering and Highway Operations

Rocky Hill, CT 06067

(860) 258-0316

Digital Processing Systems

Markham, Ontario, L3R 4T5 Canada

(905) 944-4000

Fax: (905) 944-4200

E-mail: [email protected]

Web: www.dps.com

EG&G Optoelectronics

Salem, MA 01970

(508) 745-3200

Fax: (508) 745-0894

E-mail: [email protected]

Web: www.egginc.com/ optoelectronics

Encoder Products of Canada

Toronto, Ontario, M6A 1Z4 Canada

(416) 256-1515

Fax: (416) 256-4140

E-mail: [email protected]

Gateway 2000 Inc.

North Sioux City, SD 57049

(800) 846-2000

Web: www.gateway.com

HB Communications

North Haven, CT 06473

(203) 234-9246

Fax: (203) 234-2013

Web: www.hbcomm.com

I-Bus

San Diego, CA 92123

(800) 382-4229

Fax: (619) 268-7863

E-mail: [email protected]

Web: www.ibus.com

Imagraph Corp.

Chelmsford, MA 01824

(508) 256-4624

Fax: (508) 250-9155

Web: www.imagraph.com

In-Sync Corp.

Bethesda, MD 20814

(800) 864-7272

Fax: (301) 657-5071

E-mail: [email protected]

Web: www.in-sync.com

Leica

Torrance, CA

(310) 791-5345

Web: leica.com

Nova Systems

Canton, CT 06019

(860) 693-0238

Fax: (860) 693-1497

Web: www.nova-sys.com

QNX Software Systems Ltd.

Kanata, Ontario, K2M 1W8 Canada

(800) 676-0566

Fax: (613) 591-3579

E-mail: [email protected]

Web: www.qnx.com

Roadware

Paris, Ontario, N3L 3T6 Canada

(800) 828-2627

E-mail: [email protected]

Web: www.roadware.com

Selective Electronic Inc.

Southfield, MI 48075

(313) 355-5900

Fax: (313) 355-3283

Web: www.mdc.net/~orion/ selcom.htm