Vision system targets drugs

In developing systems for a highly regulated industry such as pharmaceutical packaging, machine-vision vendors must be fully aware of the regulations initiated by the US Food and Drug Administration (Rockville, MD, USA; www.fda.gov), in particular, the 21 CFR Part 11 requirements. This regulation establishes rules to replace paper records and handwritten signatures with electronic records and digital signatures (www.21cfrpart11.com). Inspection solutions targeted at pharmaceuticals must address these requirements. For instance, products from Systech International (Cranbury, NJ, USA; www.systech-tips.com) offer multilevel security access and control, combined with a complete, secure audit trail to track all events related to production.

"What drove the development of our inspection solutions for the pharmaceutical industry," says Gaetan Spake, director of marketing and business development for Systech International, "is that our customers need to deploy integrated packaging-automation systems that ensure product security and traceability from packaging to final delivery, while meeting regulatory compliance."

The company's Tips Sentri CX and Tips Sentri MX inspection products are imaging systems that combine vision, lot-based production management, a configurable operator interface, and connectivity to other devices. They are fully 21 CFR Part 11-compliant. At the heart of these systems is a PCI-based industrial computer, packaged in a stainless-steel enclosure for reliable operations.

Tips Sentri software architecture relies on the host computer for its processing, offering very high performance. Systech's PCI-based frame grabbers enable concurrent asynchronous acquisitions from digitally controlled cameras. According to Spake, Tips Sentri solutions are usually configured with 656 × 494 × 8-bit and 1296 × 1016 × 8-bit, color and monochrome cameras, operating at acquisition speeds ranging from 10 to 200 frames/s. To accommodate the customers' specific applications, the system has the flexibility to support a variety of additional cameras.

To interface the inspection system to factory-floor peripherals such as programmable logic controllers (PLCs), I/O devices, and reject mechanisms, Systech has developed a Vision Interface Kit Master (VIK Master) that communicates over an RS-232 serial link with the host PC. The VIK Master interfaces with up to eight peripheral VIKs using a single Tips Link cable for each. It leverages the CanBus protocol to ensure real-time communication of information such as inspection results (pass/failed), time stamping, and status. The Tips Link cable also provides power and controls triggers and strobe signals. In a typical inspection setup, a VIK is used to set camera triggers and lighting strobes and to control discrete output to a PLC that, in turn, may generate a signal to an automated reject mechanism on the line.

null

null

In a typical pharmaceutical manufacturing process, several inspections may occur, including barcode, cap, and label verification. By networking machine-vision systems with other peripherals on the production line, the complete process can be tracked to comply with 21 CFR Part 11.

Peripheral VIKs can be installed near the inspection point and remotely connect to the Tips Sentri using a single cable, significantly simplifying the cabling. When needed, Tips Sentri can also communicate to networked devices and PLCs using Ethernet.

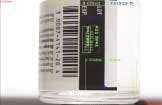

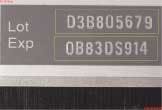

In this way, several peripherals can be remotely located while remaining under the control of the PC-based Tips Sentri system. "On each pharmaceutical packaging line," says Spake, "a number of packing inspections can be performed. For example, on a vial line, a single Tips Sentri system could inspect an invisible Data Matrix code to identify the product; check the stopper and cap placement; and inspect the lot, expiration date, and barcode overprinted on the label and the labels applied to carton or cases. The same system could also run cap color and case-content inspections. More and more though, our customers want to globally set their line to a particular batch and collect real-time production data."

Systech offers Tips Advisor, an automation server that interfaces to machine-vision and other machines and peripherals. With such systems, the recipe management and line setup can be centrally managed and the wealth of data collected from the line devices stored into a history database. Tips Advisor allows access to share stored database information so pharmaceutical manufacturers can perform complete electronic tracking of the manufacturing process. In this manner, the server can be used to remotely configure, for a specific production lot, Tips Sentri Vision systems, barcode readers, printers, PLCs, and weigh-scale products on the pharmaceutical production line.