EMVA-1288 Standard: Camera test systems go on show at VISION

More than five years ago the European Machine Vision Association (EMVA; Frankfurt, Germany; www.emva.org) started an initiative to define a unified method to measure, compute, and present specification parameters and characterization data for cameras and image sensors used for machine-vision applications. This standard, known as EMVA-1288, is intended to provide specifications for both sensors and cameras so that system developers can easily compare camera specifications or calculate system performance.

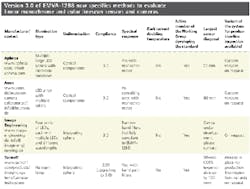

In November 2010, the EMVA announced the latest revision, Version 3.0, which allows monochrome and color area and linescan cameras with linear photoresponse characteristics to be compared. While analog cameras used in conjunction with a frame grabber can be described according to EMVA-1288, digital nonlinear cameras, electron-multiplying cameras, and those that are sensitive in the deep ultraviolet still remain uncovered.

To evaluate and characterize parameters such as quantum efficiency, signal-to-noise ratio (SNR), and the nonuniformity and nonlinearity of cameras, a number of different companies now offer off-the-shelf automated systems. One of the first companies to develop such a system, Sarnoff (Princeton, NJ, USA; www.sarnoff.com) first introduced its Camera Commander system at Photonics West in January 1999.

The system, designed by Jongin George Kim of the company’s Imaging Products Division, focuses on monochrome digital area-scan cameras with linear photo response characteristics because the original EMVA-1288 standard only encompassed these cameras (see “Comparing Sensors and Cameras,” Vision Systems Design, March 2009).

Now, however, three European manufacturers have entered the market with automated test systems that are compatible with Version 3.0 of the EMVA-1288 standard: Aphesa (Harzé, Belgium; www.aphesa.com), the AEON Camera Calibrator from Aeon Verlag and Studio (Hanau, Germany; www.aeon.de), and the Sensator from Image Engineering (Frechen, Germany: www.image-engineering.de). All of these systems were shown at the EMVA-1288 standards booth at the November VISION 2010 show in Stuttgart. For a video of this demonstration, go to www.vision-systems.com.

To determine characteristics such as the quantum efficiency, noise, and spectral characteristics of an individual camera, a series of images are first captured using monochromatic light of different wavelengths. Since the standard allows for exposure time or light intensity change, images are acquired with increased exposure (amount of photons) to cover the response range of the camera with enough points.

To accomplish this, systems such as the Sensator use a built-in photodiode that can measure the intensity of these photons at the image plane. After these measurements are taken, a dark measurement is taken with the camera capped and the gray-level values between the two images computed. The data are then used to determine the quantum efficiency of the sensor or camera over a number of different wavelengths.

To provide the illumination required for these tests, manufacturers use a range of LEDs at different wavelengths. In the Aeon Camera Calibrator, for example, 470-nm blue, 525-nm green, and 630-nm red LEDs are used. To perform low-resolution spectral measurements at up to 16 different wavelengths between 365 nm and 950 nm, an optional spectral light source can be used.

Since the LED current can be controlled digitally, the illumination level can be changed either by adjusting the current to the LED or by changing the exposure time of the camera using a constant LED current. Measurements are therefore simplified since neither triggering of the camera or the light source is required. To allow developers to evaluate a range of cameras, these systems are supplied with a range of interfaces that include Camera Link, FireWire, GigE Vision, and USB interfaces from numerous third-party vendors.

Hopefully, with the advent of Version 3.0 of the EMVA standard and the use of such automated test systems, system integrators who specify sensor and camera products will no longer have to rely on sometimes inaccurate or incomplete data sheets from their suppliers.