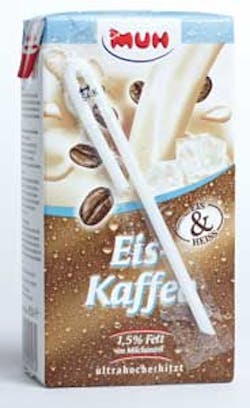

Vision sensor checks position of drinking straws

Milch-Union Hocheifel (MUH; www.muh.de) is a dairy cooperative that processes approximately 3.5 million liters of milk every day, producing 1.3 billion packages of refined milk annually.

Many of the products contain a flexible plastic drinking straw affixed to the outside of the carton. These straws must be checked to ensure that none protrudes sideways from the packaging.

Detecting the exact position of drinking straws sealed in transparent foil, against various multicolored background designs of packages of milk, poses a significant challenge. To inspect the straws, a drinking-straw monitoring system was developed by Baumer (www.baumer.com) using the company's VeriSens vision sensor. An indirect lighting system was used to illuminate the drinking straw while screening the background image, making the inspection system independent of the package design.

As the packages pass along a conveyor, a sensor is used to triggers the VeriSens camera. The system can recognize whether or not a drinking straw is attached and correctly positioned in less than 30 msec. Packages with wrongly positioned drinking straws are then ejected from the production line.