Smart camera sorts gum pellets

Vision-inspection system ensures that chewing-gum pellets are properly formed and positioned in their blister packages.

By Charles Masi, Contributing Editor

Jay Smith, sales engineer at control-system distributor R. R. Floody Co. (Rockford, IL, USA), received an interesting design problem from engineers at Cadbury Adams (Loves Park, IL, USA). They contracted him to replace foreign-made automated inspection stations built into machines used to package their Dentyne Ice sugar-free gum products. The engineers complained that they were having trouble maintaining their vision-inspection system.

One problem was that all of the system documentation was written in a foreign language that they did not understand. Another was that the software was written in C, in which they were inexperienced, and used non-English variable names and comments. More important, the inspection system was prone to component failures. As a result, the Cadbury engineers decided they wanted to remove the offending system and replace it with a US-developed machine-vision system.

Based on his experience, Smith selected a DVT Corp. (Duluth, GA, USA) camera system to replace the faulty vision system, but integrating it with the existing automated parts-handling subsystem was a difficult interfacing problem. Someone would have to reverse-engineer the system interface so that the new vision-inspection system could inform the handling system which chewing-gum blister packages were okay for sale, which to reject, and which were empty. He called on Dave McMorran, systems integrator and vice president of Dynamic Motion Control (DMC; Chicago, IL, USA), to untangle the connectivity mess.

McMorran made a survey of the vision-inspection system layout. Prior to inspection, the chewing-gum products are produced as equal-sized pellets, and the pellets are dropped into wells in a continuously formed plastic web package. Individual blister packages measure 2.5 × 4.0 in. (64 × 102 mm), and four blisters fit along the 10-in. (254-mm) width of the web. Each blister package contains one gum pellet. A web production package contains 48 blisters that are laid out as four subgroups of 12 blisters.

McMorran's task was to make sure that the vision-inspection system could check that the pellets were placed and oriented correctly in their wells and that the pellets were all properly formed. The system performs the inspection after the packaging equipment drops the pellets into the wells and before a protective thin aluminum foil is attached to each blister. After inspection, packaging equipment separates the web packages into groups of 12 blisters. To extract a gum pellet, the consumer presses on the blister to push the pellet through the foil.

Should a package blister contain a malformed or disoriented pellet, or the pellet is missing, the system has to detect the error, identify which package contains the error, and inform the packaging equipment. This equipment has to identify defective blister packages and eject them into a reject bin.

Hardware setup

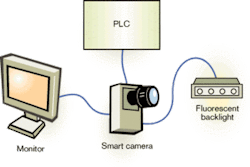

McMorran centered the new vision-inspection-system architecture on the DVT Legend 540 SmartImage camera (see Fig. 1). This camera contains a 1/3-in.-format CCD with 7.4-sq µm pixels that deliver 640 × 480-pixel resolution. Key features include 10-µs to 1-s electronic shuttering, eight configurable digital inputs and outputs, CS-lens mounting, and an RJ-45 connector for 10/100-Mbit/s Ethernet communications.

Other system components include a fluorescent backlight illuminator, an FPM-38T flat-panel monitor from Advantech (Irvine, CA, USA), and a PLC-5 programmable logic controller from Allen-Bradley (Milwaukee, WI, USA). The PLC formats the system output for subsequent processing by a packaging machine (see Fig. 2). The monitor provides technicians with images of the blister, identifies failed packages, and lists data and production statistics.

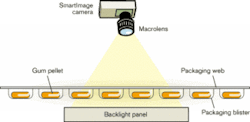

Tension in the packaging web supports the products under inspection as they pass through the inspection station. McMorran decided to use a linear fluorescent tube behind a diffusing panel to backlight the web. This lighting subassembly sits approximately 2 in. (50 mm) beneath the web as it passes through the inspection station (see Fig. 3).

A Model LTS-03Z f/1.4 lens made by Tamron USA (Commack, NY, USA) collects the images and forms a shadowgraph on the camera's CCD sensor (see Fig. 4). The smart camera's CCD array and built-in control/imaging computer are designed for high-speed inspection rather than high image resolution.

As blister packages are placed on the continuous web, a trigger signal is sent to the camera so that an image is taken every time four blisters are observed. Then, the camera's computer and software perform inspections of the images to determine whether the packs are empty or contain gum of the correct size. If a blister is empty, an output is transmitted to the system PLC, which directs that blister to a recycling container. Blisters that contain defective gum pellets are sent to a failure bin via separate outputs for each of the four blisters inspected at once. Typical operating speed of this line is 300 packs/minute (75 inspections/minute).

"We're looking for presence or absence," McMorran says, "to make sure all the blisters are filled. Then we look for misshapen pieces, such as gum pellets with a corner broken off. We also look at their rectangular shapes and make sure that each pellet falls within specifications. Lastly, we look for foreign objects and to catch instances where an extra pellet gets put in."

Software processing

The vision-inspection system images four blister packages at a time for three consecutive columns, for a total of 12 pellets. McMorran set up the camera sensor's FrameWorks software with four blob sensors to look for the presence or absence of pellets in each package. Essentially, the software identifies the blobs visible in the image and counts them. It looks for at least 12 pellets to ensure that all of the blisters are filled. Should 13 blobs appear, an additional-pellet fault would be detected. Then, the 12-pellet sequence is repeated until the production run is completed.

The software also includes a scanning feature counter to find defects in the pellets. The sensor sees three features—three rectangular blobs represent the three pellets in the first row of the first web package of 12 pellets. Feature counters are also arranged in columns, which see four features representing the four pellets arranged vertically. Defects manifest themselves if any scanning line detects a feature edge outside of the feature-size tolerance range. Performing the tests in this way allows the software to find both under- and oversized pellets.

The software uses two foreground scripts for each 12-pellet web package to compile the results of all of tests. The first set of foreground scripts determines whether to pass the package, while the second set of foreground scripts determines whether a given package is completely empty. If a package is completely empty (that is, no blobs are detected), then the controlling PLC sends the package to a recycling bin instead of to the reject bin.

Interfacing challenge

Getting the vision system to communicate with the PLC was a major design task. McMorran worked with William Evink, electronic specialist at Cadbury Adams, to reverse-engineer the PLC code and I/O sequence. "We had to determine the I/O sequence that the PLC needed to synchronize camera triggering," McMorran recalls, "as well as coordinating the reject mechanism, which happens after the parts are separated."

If the vision system sees a bad package, that package does not get rejected until later, when it drops down a reject chute after being separated from the rest of the web package. McMorran had to make sure that all the inspection functions worked properly to mimic the original vision system. Of course, with no usable documentation available for the original system, a great deal of design experimentation was carried out to make sure that the new vision system was correctly integrated.

The replacement vision inspection system proved successful. Cadbury Adams was pleased that the system was easy to use and could be supported locally. The company has replaced its older vision systems on all the packaging machines they already had in-house. In addition, Cadbury Adams has directed the packaging-machine manufacturer not to include the older vision inspection systems on any new packaging machines, as the company expands its production lines. Instead, it is installing the new vision-inspection systems based on McMorran's design.

Coming in October

Vision inspection system highlights acrylic sheet defects

Company Info

Advantech www.advantech.com

Allen-Bradley www.ab.com

Cadbury Adams www.dentyneice.com

Dynamic Motion Control www.dmcinfo.com

DVT Corp. www.dvtsensors.com

R. R. Floody Co. www.rrfloody.com

Tamron USA www.tamron.com

features, advantanges, benefits

William Evink, electronic specialist at Cadbury Adams, says, "The features we like most about this new smart-camera-based vision-inspection system are its compact size, flexible real-time monitoring system, and easy-to-use software. Operators especially like the fact that they can go on-line to see what the vision system sees at any time. In addition to viewing the current image, they can step back to review the last failure or view tables of historical data.

"Engineers were pleased with the free training they received in how to use the software to modify system parameters. They didn't have to memorize lists of commands, and they didn't have to go through a lengthy process of teaching the system to recognize failures. The earlier foreign-built system was prone to breakdowns, which were a major problem because of the language barrier and difficulties in getting replacement parts. The new system is supported by a local distributor. So far, we haven't had any component failures to worry about."