Vision systems match vehicle ID numbers

Smart-camera-based inspection systems capture car-frame identification numbers using template-matching and neural-network software.

By R. Winn Hardin, Contributing Editor

In the automotive industry, stamped vehicle-identification numbers (VINs) uniquely identify a production-line automobile. Automobile manufacturers must stamp an official VIN on every car's frame and duplicate it on stickers and barcodes located at various places around the exterior of the automobile. If these numbers do not match, then the manufacturer must scrap the vehicle at a high cost. Even in highly automated automobile-manufacturing plants, incorrect VINs are still discovered on a few chassis.

Nissan Motor Manufacturing (UK) Ltd. (Sunderland, UK) used to stamp the official VIN in the engine compartment. When the vehicle reached the 'finishing line,' just prior to final waxing and shipping, an operator examined the engine compartment, compared the stamped VIN number with the VIN number listed on the automobile's manifest, and subsequently made a pass/fail decision. Now, however, several new car models have their VIN stamped in a compartment under the carpet located in front of the driver's seat.

For this situation, the operator has to climb into the vehicle, open the compartment, and, with the help of a flashlight, visually read the VIN number. This inspection procedure, however, has proved to be a health and safety hazard, as inspectors frequently injured themselves, according to Earl Yardley, director of Industrial Vision Systems Ltd. (IVS; Wantage, Oxon, UK). Consequently, Nissan decided to install an automated vision-inspection system.

Using an automated system

Nissan chose IVS from among several systems integrators to perform VIN inspection with an automated vision system, mainly because the company provides NeuroCheck software (NeuroCheck GmbH; Remseck, Germany). This software offers a configurable optical-character-recognition (OCR) platform without the need for complex code. In addition, IVS is an experienced supplier of database-management software and networked vision systems.

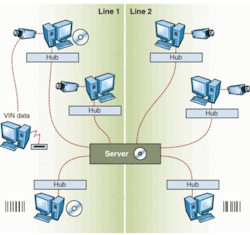

To meet the operational needs of the automobile-production lines, IVS integrated both off-the-shelf and custom hardware and software. The resultant VIN vision-inspection system comprises multiple image-acquisition stations and displays, OCR and neural-network software, and a database to store images and other data during the 24 hours it takes for an automobile to reach the finishing production lines (see Fig. 1).

Nissan uses four production lines to manufacture three automobile models at its Sunderland plant. Two production lines for each model feed into a single product-finishing line. From beginning to end, an automobile travels approximately 2.5 km during its production and manufacturing processes.

At an initial production step, each automobile frame is stamped with a unique VIN by a robotic device controlled by an Omron (Hoofddorp, The Netherlands) programmable logic controller (PLC). An ASCII data string is provided by the Nissan plant's line PLC, which supervises the Omron PLC. Accepting data from both PLCs, the IVS custom VIN imaging system runs NeuroCheck software.

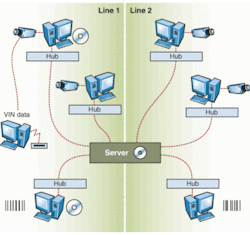

The system PC collects the ASCII data string representing the VIN number from both PLCs, and the NeuroCheck software temporarily stores the data in PC memory. After the line robot stamps the VIN number into the automobile frame, it communicates the data to the VIN imaging system through an Omron Sysmac Link PLC card. The NeuroCheck software then triggers a 752 × 582-pixel IVS V10 1/2-in. black-and-white CCD camera fitted with a 25-mm lens from Pentax Benelux BV (Zavertem, Belgium) and a polarizing filter to acquire an image. Key camera specifications include 570-TV line resolution, 56-dB signal-to-noise ratio, 0.2-lux minimum illumination, and electronic shuttering to 1/10,000 s.

A pair of NeuroCheck IVS-LFL-301-R red LED light arrays with crosspolarizing filters is placed at oblique angles to the VIN stamp to provide efficient imaging illumination and to help limit spurious reflection from the metal surface. All of the image-acquisition systems used on the four production lines are positioned on an Armagard (Essex, UK) pedestal and are protected by a custom housing designed by IVS to accommodate the robot work cell that performs the specific VIN stamping (see Fig. 2).

"We use fixed-focus manual-iris lockable lenses, and, for the Micra auto line, we use a X2 [focus] range extender," Yardley says. The camera acquires an image and sends the 8-bit gray-scale data file across a 12-pin serial cable to a Matrix Vision (Oppenweiller, Germany) MV-SG frame grabber. This frame grabber works with industry-standard cameras, offers variable resolution and variable scan rates, and accommodates images up to 4k × 4k. "If we need to go to a higher resolution at some point, we know that we can," Yardley explains.

Database keeps track

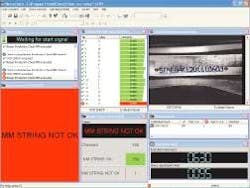

After the image has been imported into PC memory, the NeuroCheck software uses a combination of template-matching and neural-network-classifier tools to perform OCR on the stamped VIN numbers and alphabetic letters. These tools can read any type of font, instead of only industry-standard OCR A and OCR B fonts (see Fig. 3). "We don't use special fonts and variability, and size is not an issue with the NeuroCheck software because we can deal with scaling," Yardley says.

After identifying the VIN string, the software compares that string against the ASCII strings from the robot and line PLCs. "Even if the line PLC sends the correct VIN to the robot PLC, you can still get errors. So we check against the character strings from both PLCs," Yardley adds. A bit-mapped version of the image, the robot and line PLC ASCII strings, and a 'pass/fail' code are all sent across the Sunderland plant's local-area network (LAN) and stored in a Microsoft SQL database on a central Compaq server for later retrieval.

As the cars pass the finishing line, an operator uses an Intermec (Everett, WA, USA) 1551 barcode scanner attached to another Compaq PC to scan the manifest sheet that accompanies each car. To verify that the sticker VIN matches the stamped VIN, the PC takes the ASCII string from the barcode reader and sends it across the LAN as a query to the Microsoft SQL database. When a match is found, the original VIN image is recalled, and the operator compares the VIN string in the image to the VIN on the manifest sheet for a match. Based on these checks, the automobile plant officials can be sure that the VIN number of the vehicle is correct, and the automobile can be delivered to the final waxing and shipping station.

"We could perform the VIN check without displaying the stored VIN image," Yardley comments, "but, by examining this image, the operator can also spot other problems, such as a worn stamping tool or weld splats. If a tool can be fixed before it fails, that's a bonus."

The Nissan plant produces approximately 2500 cars a day. It also produces 2500 images on the SQL database. Every few days, the VIN images are removed from the central server to conserve storage capacity.

Company Info

Armagard Ltd.www.armagard.co.uk

Industrial Vision Systems Ltd.www.industrialvision.co.uk

Intermec Technologies Corp.www.intermec.com

Matrix Vision GmbHwww.matrix-vision.de

NeuroCheck GmbHwww.neurocheck.com

Nissan Motor Manufacturing (UK) Ltd.www.nissan-global.com

OMRON Europe BVwww.omron.com

Pentax Benelux BVwww.pentax.be