Thermal imaging cameras detect refrigerator leaks for UK maintenance company

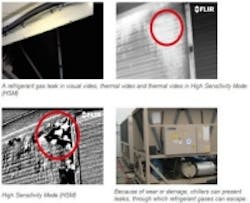

In order to detect potential refrigerant gas leaks in its chillers, property maintenance service company Integral UK used FLIR thermal imaging cameras, which helped to save energy, locate a lack of insulation, and identify hotspots in suspected leak areas.

Integral’s range of services includes mechanical and electrical engineering, fabric maintenance, energy and environmental services, and solutions for fire prevention and protection. Because leaks in chillers can cause long term damage and also shorten the life cycle of the product, Integral decided to conduct field tests using a FLIR GF304thermal imaging camera.

These cameras from FLIR are specifically designed for the detection of refrigerant gases without the need to shut down an operation. The cameras contained a cooled quantum well infrared photodetector and a cold band pass filter which allows it to visualize gases in the 8 – 8.6 µm waveband. FLIR GF304 cameras can visualize temperatures from -20°C to 500°C (-4°F to 932°F). In addition, the cameras come with either a fixed 14.5° lens or with a fixed 24° lens.

After the cameras capture images of the area of a suspected leak, FLIR’s reporting software enables Integral to provide a report to its client, which includes a visual representation of the problem allowing him or her to be better informed about the extent and impact of the issue.

Prior to using the FLIR cameras, the identification of refrigerant leaks using traditional methods had proved to be difficult, says Martin Popowicz of Integral UK.

"It has always been difficult to detect refrigerant gas leaks from our chillers. The recent field trial with FLIR however has been most impressive, enabling us to locate and rectify, with greater accuracy and efficiency than ever before, providing clients with early energy savings and far better reliability."

In one particular example, Integral explained that a subcontractor chiller company told them they had a suspected leak refrigeration leak, so Integral brought a FLIR G304 camera to see if they could identify one. The very next day, the camera was able to show that there was no leak, which replaced the need to degas, check for leaks, and recharge the chiller – an operation that can take a week or more. As a result, this particular client was able to keep its chiller operational, saving them both time and money.

View the FLIR case study.

Also check out:

FLIR thermal imaging cameras chosen for UK Search and Rescue program

Vision system monitors bat behavior in research project

Thermal imaging system protects whales from underwater noise pollution

Share your vision-related news by contacting James Carroll, Senior Web Editor, Vision Systems Design

To receive news like this in your inbox, click here.

Join our LinkedIn group | Like us on Facebook | Follow us on Twitter | Check us out on Google +

About the Author

James Carroll

Former VSD Editor James Carroll joined the team 2013. Carroll covered machine vision and imaging from numerous angles, including application stories, industry news, market updates, and new products. In addition to writing and editing articles, Carroll managed the Innovators Awards program and webcasts.