Vision system monitors flame

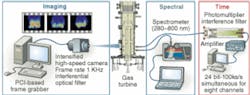

Italian researchers are using a vision system combined with an image intensifier to investigate the combustion process in the gas turbines of a power station. The team is trying to minimize the dangers caused by burning instability and to cut exhaust pollutants while improving power generation efficiency under widely differing operational conditions.

ENEL, a €30 billion gas-and-power-generation and distribution company (Rome, Italy; www.enel.it), has been conducting flame research at its research facility in Livorno, 300 km northwest of Rome, for several years. In 2002, the research division deployed a HI-CAM vision system from Lambert Instruments (Leutingewolde, The Netherlands; www.lambert-instruments.com) to enhance gas-turbine research. The vision system consists of a CMOS-based HCC-1000 camera from VDS Vossk

To observe the desired detail in the dynamic combustion process, a high frame rate is needed (2000 frames/s), as well as a short exposure time-even shorter than the frame rate allows. At such a short exposure time the number of photons becomes too low to provide enough signal compared to the noise of the not-intensified camera. To solve this problem, the image intensifier acts as an optical preamplifier in front of the camera's image sensor.

The intensifier detects individual photons and amplifies them approximately 10,000 times to give a signal much higher than the noise of the camera. By gating the intensifier, very short exposure times can be applied. "However," says Lambert's managing director Bert van Geest, "it should be noted that the photon noise that becomes noticeable at low numbers of photons is still present when using an image intensifier."

Enrico Paganini, a researcher in ENEL's Generation & Energy Management division, says, "We are studying two main topics: identifying process instabilities and characterizing the combustion conditions inside the turbine. We apply the vision system to a laboratory-scale combustor, a Rickie tube, and an industrial gas-turbine combustor at atmospheric pressure [the 0.5-m3 test reaction vessel delivers a power of 700 kW]. We are planning to apply the system to an industrial gas-turbine combustor at full-scale pressure using a fiberoptic coupling."

The image of the flame in the turbine is made using interferometric filters, typically at a wavelength of 310 nm, to analyze emissions of the hydroxyl group (OH-) in the gas mix because the distribution and quantities of this ion are directly related to the combustion of methane and hydrogen, the fuels under consideration. The vision system also gathers dynamic information about the flame itself, which involves analysis at a rate up to several hundred hertz. The small spectral bandwidth and the very short exposure necessary reduce the light from the reaction; hence the need for the high-speed, intensifier-supported camera.

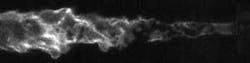

A critical observation made by the researchers is the transition between a low-pressure oscillation and a strong oscillation. The frame rate is approximately 500 Hz, and image dimensions are approximately 100 × 150 mm. Paganini says, "It's important to note in the flame the very different spatial distribution of the oscillation. It is more vertical in the first case and more horizontal in the second. We are further analyzing the modes of oscillation in the two cases to quantify these observations. We have found that there are two different modes with different frequency of oscillation so we can also associate different frequency of oscillation to different spatial modes.

"For the first two years we worked without imaging the burning process, but since installing the vision system we have been able to identify the flames' vertical and horizontal burning modes. The energy of these modes changes as the burning mixture reaches its instability point, at which the pressure rises. Before that point is reached there is a danger point [where there is a risk of explosion] just before the dramatic pressure increase in the combustion chamber."

Lambert Instruments has developed the II25 intensifier to be optically (lens) coupled to high-speed cameras and readily attached to or removed from the camera. Lambert's van Geest says, "We have also sold a HI-CAM to Cardiff University (Cardiff, UK; www.cf.ac.uk) and one to Osnabrück University (Osnabrück, Germany; www.uni-osnabrueck.de), both for microscopy applications. And we have made our first sale of the II25 to the Sintef Energy Research high-voltage research department (Trondheim, Norway) for other uses. Other markets that we hope to sell into are biomedical research and crash testing."