Disk techniques boost image storage of optical drives

Disk techniques boost image storage of optical drives

R. Winn Hardin

Contributing Editor

For machine-vision, medical, scientific, and military imaging, optical-disk storage and archiving systems perform an important role in data recording. Rugged optical disks, such as the compact-disk (CD) series of storage devices, phase-change recording devices such as the digital versatile disk (DVD) series, and polarization-dependent magneto-optical (MO) disks, offer a shelf life of more than 30 years without the risk of data degradation. By combining several optical disks into a single jukebox station, optical and MO disks compare and sometimes surpass the capacity and access speed of magnetic media while offering rugged storage and freedom from accidental erasure or damage by magnet fields or electric charges (see "Comparing optical-disk technologies," p. 74).

Currently, standard 5.25-in. optical CD, DVD, and MO disks offer storage capacities of up to eight times that of the 650-Mbyte storage capacity of compact disks and provide a total capacity on a dual-sided or dual-layer MO disk of 5.2 Gbytes. Unfortunately, the capabilities of current storage systems to pack more data into a given area are nearing the physical limitations imposed by semiconductor lasers and optical assemblies. As a result, optical-drive and media manufacturers are developing new ways to increase the areal density of optical disks and to challenge the market controlled by conventional high-capacity-tape image-archival systems. While some of these optical-storage technologies have just been introduced, others are expected within the next 12 months.

DVD choices

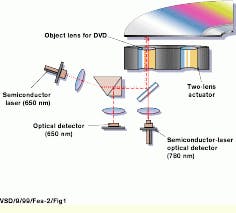

Confronted with DVD ROM, recordable, write-once read-many (WORM), RAM, and read/write options, system integrators must deal with numerous storage-design choices. As usual, pricing is a major consideration, such as the high cost of DVD-RAM devices ($500-$700 per drive). Moreover, performance, such as the DVD-RAM`s ability to collect and store data in nonsequential blocks quickly, isolates this device from other optical-storage solutions (see Fig. 1).

Many DVD-RAM devices are geared to industrial- and medical-imaging applications for which high capacities with random data access are mandatory. These devices include the GF-1000 from Hitachi (Fair Lawn, NJ) and the LF-D101U from Matsushita Electric-Panasonic (Tokyo, Japan). These DVD-RAM drives use a germanium antimony telluride (GeSbTe) media for recording. The Matsushita-Panasonic LF-D101U interfaces through a SCSI-2/Fast SCSI format and comes with a 2-Mbyte buffer to boost data-transfer rates to 1.385 Mbyte/s. However, its slow 120-ms-seek and 140-ms-access times illustrate why optical and MO storage devices lag behind magnetic-storage options.

Last June, the Japan DVD Forum adopted specifications for the next generation of Japanese DVD-RAM drives that will use smaller pitch and bit sizes to double media storage capacity to 4.7 Gbytes per side. Early releases of these drives are expected by year`s end.

Matsushita Electric-Panasonic has also presented a new design concept that builds upon the dual-layer recording medium of DVD-ROM. Unlike current DVD-RAM disks, DVD-ROM disks use two recording layers, usually made of aluminum and gold. The upper gold layer is thin, semi-transparent, and partially reflective. In operation, the read laser transmits through the upper layer and reads data on the lower, more reflective, aluminum layer.

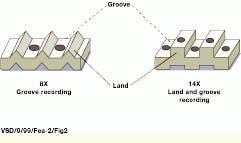

According to optical-media engineer Nobuo Akahira of the Matsushita Electric (Osaka, Japan) optical-disk-systems development center, Panasonic`s upcoming drives will use two layers of GeSbTe with a partially reflective coating on the upper layer, similar to the DVD-ROM disk. By including land-and-groove recording, in which bits are stored not only on the flat surface of a media but also in the deeper grooves that are used for tracking, Matsushita plans to deliver an optical disk with 8.5-Gbyte storage capacity per side, for a total of 17 Gbytes (see Fig. 2). Although the DVD Forum believes that 17 Gbytes is the maximum storage capacity for DVD drives, Akahira estimates that DVD capacities of 27 Gbytes will be possible with the advent of blue-emitting semiconductor lasers.

DVD-RAM drives offer another benefit, as well. Both the GF-1000 and LF-D101U contain dual optical heads, making the devices backward compatible with other DVD technologies and compact disks.

Super resolution

Many archiving applications, such as for military and medical uses, require the storage of images as large as 16k x 16k pixels. To meet such requirements, optical-disk manufacturers have turned to a combination of magnetic- and optical-storage technologies.

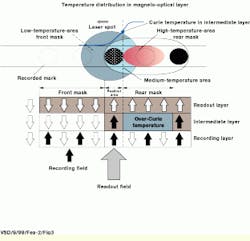

Next-generation MO technologies, which are being championed by companies such as Sony Electronics (Park Ridge, NJ) and Fujitsu Ltd. (Tokyo, Japan), are already available. Similar to the 120-mm drives slated for release next year, Fujitsu`s MSD3130SS 3.5-in. GigaMO drive uses magnetically induced super-resolution (MSR) techniques to store 1.35 Gbytes on a single 3.5-in. removable disk (see Fig. 3). The MSR technology, based on the IRISTER method developed by Sony in 1991, can record bit sizes much smaller than the wavelength of the writing laser.

Sony and Fujitsu both break existing physical limitations by using several layers of MO material on a single disk and a strong external magnet and coil for focusing and tracking along the optical disk. According to Masataka Ogawa, Sony director of business planning, data are stored on the bottom layer of three layers that make up an overall MO recording layer. In operation, a write laser is focused on the recording layer. The most intense portion of the Gaussian profile of the beam induces thermal flux on the recording layer. Within this area, a bit is recorded by polarizing the recording media with the external magnetic field of the magnet. "MSR recording uses the same process as previous systems," explains Ogawa. "Writing is done directly on the recording (bottom) layer, and the top layer polarization disappears."

The most important difference in MSR lies within the reading of its small-recorded pits, which ordinarily would be unreadable because they surpass the optical resolution provided by the laser`s wavelength and optical lens. Reading small pits, however, causes the system signal-to-noise ratio (S/N) to decrease, producing read errors. Land-and-groove recording schemes, in which neighboring bits can further decrease the S/N, complicate this situation. To eliminate this problem, Sony and Fujitsu use the MSR technique for readout.

In operation, the readout layer assists in making the small pits readable by the optical head. The original concept of MSR was to have recorded pits copied to the readout layer so that the data became readable. In the case of GigaMO, without heating by a laser beam, the readout layer remains in a neutrally polarized state. Once the laser beam illuminates the readout layer, heat increases in the readout layer, which is then magnetically aligned with the bottom-layer polarization. This causes a partial Kerr rotation (a nonlinear effect exhibited by recording media that results in a polarization shift of the beam) within a portion of the beam spot area. As a result, the return optical signal is modulated without any interference from adjacent pits.

Sony`s marketing manager of magneto-optical drives, Toshi Kawai, expects the 14x, 9.1-Gbyte, 5.25-in. (120-mm) MO disk drives to be released next year. To ensure backward compatibility, Kawai says that the new systems will use the same light sources as previous systems (650 nm) and have a single-head read mechanism that requires operators to turn the disk over to access data on the other side. According to Kawai, dual-head systems add too much cost to the drive.

Other technologies

According to Dan Cautis, senior vice president of product development at Maxoptic (Fremont, CA), maintaining backward compatibility limits the ability of next-generation MO storage devices to compete viably with tape and hard-drive storage devices. Much higher capacities of 40 and 80 Gbytes are needed, as well as faster transfer rates of 30 Mbytes/s. "The question was do we want to stay compatible. We could have tried to go one or two more generations, but it wouldn`t make any sense."

To achieve these performance goals, Maxoptix developed an optical-super-density (OSD) recording technique. According to Cautis, the first products to use this technology will be available by the end of next year. The OSD technology brings together several new processes including land-and-groove recording and MSR.

A key difference, however, is the Maxoptix OverCoat Incident Recording (OCIR) process. Reducing the thickness of the acrylic overcoat on the optical disk from 0.5 mm to between 5 and 40 μm means that the flying MO head can be placed closer to the recording layer, focusing lenses can be used with higher numerical apertures (NAs), and smaller magnetic coils with faster switching times can be installed. Conventional MO and DVD recording devices use lenses with a NA of 0.55 or 0.6. Maxoptix expects to achieve a NA of 0.8 in its next-generation device.

OCIR is a compromise between the Air Incident Recording used in hard drives and Substrate Incident Recording (SIR) used in MO drives. "Two optical pickups are used on each side to produce 30 Mbytes/s transfer rates," Cautis says. "That`s six times faster than digital linear tape (DLT), three times faster than super DLT, and about four times faster than single-sided, 8x MO disks," says Cautis. To date, Maxoptix has demonstrated all the individual servo and mechanical parts for the drive, including the new fabrication process for the NA lens.

Near-field recording

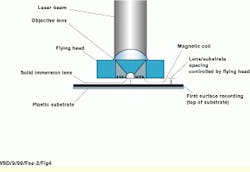

To meet growing demands for DLT and hard-drive storage for high-end image-archival and data-storage applications, TeraStor (San Jose, CA) is redirecting its efforts in MO storage. Using a technique based on microscopy, called near-field recording, TeraStor uses a standard NA lens to focus the recording beam on a point at the bottom of a solid immersion lens (SIL) located just below the first lens (see Fig. 4). The solid immersion lens is important because it retards the passage of light, shortens the wavelength of the original beam, and creates a smaller focus spot than initially possible.

To couple the focal spot to the recording media, TeraStor places the recording substrate on the surface of the disk and moves the recording head to within 0.15 μm (the near field) of the disk surface. By placing the flying head at a distance of less than the wavelength of light, the incident light crosses the boundary between the SIL and the disk surface and evanescently couples at a significantly smaller focal spot and wavelength. This technique results in a loss of optical power; however, enough power remains to efficiently read the data. For many years, microscopists have used this technique of placing a sample closer to the objective than the wavelength of illuminating light to resolve objects below the theoretical resolution of the optical system.

According to Jonathan Hubert, TeraStor director of product marketing, the company plans to release a 20-Gbyte, dual-sided, removable-cartridge system next spring with a 40-Gbyte version hitting production in fourth-quarter 2000. The drive is projected to provide transfer rates of 6 to 12.5 Mbytes/s, depending on the location of the data on the disk. However, this format requires that the disk must not be touched by users, which dictates that a dual-cartridge design and autoloading must be used in the drive.

Hubert says that TeraStor has already developed relationships with jukebox station and automation manufacturers to promote the drives. "Optical storage has a good and bad reputation. It`s good for reliability--that`s why it`s used in medical imaging--but bad for cost per gigabyte and performance," he adds. By increasing areal density and performance while lowering costs, companies such as Sony, Fujitsu, Maxoptix, and TeraStor are anticipating that such drives will eventually compete with magnetic media.

Comparing optical-disk technologies

Standard recordable optical disks, such as compact disks (CDs), generally use a single optical-head system for erasing, recording, and writing. Recordable CDs use a high-intensity beam of approximately 750 nm to melt the recording layer and erase the data stored as pits or burn holes. During the writing process, the same beam is focused through a polymer protective layer to heat the recording medium underneath, therefore creating surface pits. A low-intensity beam reflects off these pits in an amplitude-modulated method that represents zeros (0s) and ones (1s).

Digital versatile disk (DVD)-RAM technology uses some of the same recording materials and methods. To increase the CD recording capacity from 680 Mbytes to the current standard of 4.7 Gbytes, DVD technology essentially halves the pitch (width of a track) and the pit length while writing bits on both the flat surface of the media (land) and the spiral track (groove).

Unlike CD polymer or magneto-optical (MO) media, DVD technology uses a phase-change-recording medium, such as germanium antimony telluride (GeSbTe) to store data. This material, lying underneath a polymer protective coating, is reflective in its crystalline state or less reflective in an amorphous state. To write data onto the disk, a laser beam heats the material above its 600°C melting point. As the material cools, it becomes amorphous and less reflective.

By using the same optical system at lower power values, the temperature of the material can be raised to just above the 300°C crystalline-forming point. By slowly powering down the laser, the recording material cools and returns to its crystalline state, erasing all data. Reading the data calls for the use of a low-intensity beam and a measurement of the amount of reflected light.

Magneto-optical disks use a different method to write data to a recording medium. In this case, the write head is coupled to a magnetic coil. The recording medium is heated into a state of flux by the system laser. The magnet then polarizes the semi-liquid material by shifting its magnetic field. Positive or S-direction MO material represents a one (1), negatively polarized material represents a zero (0), and neutrally polarized media represents empty space. Data are retrieved by reading the polarity of the reflected read beam.

Despite technology improvements, the demand for fast and accurate recording media in industrial, medical, scientific, and military archival and storage applications continues to outpace device performance. Therefore, the optical-storage industry is turning to multilayer disks that stack data like floors in a building, fast-switching magnetic fields to modulate read/write laser heads, new edge-reading techniques to increase areal densities, and crescent- rather than circular-shaped bits.

FIGURE 1. Hitachi GF-1000 DVD-RAM drive contains two semiconductor lasers and lens assemblies to ensure backward compatibility with existing all-optical drives. The optical heads are installed in a disk whose rotation depends on the recording media used.

FIGURE 2. The magnetically induced super-resolution technique uses temperature distribution in an intermediate layer of magneto-optical material to mask portions of the read laser to read recorded bits that are smaller than the wavelength of the light source. (Courtesy Sony Electronics)

FIGURE 3. Land-and-groove recording boosts the media recording area by 25% or more, depending on the track pitch of the individual technology

FIGURE 4. Evanescent coupling is accomplished by placing the magneto-optical head closer to the surface than the wavelength of light used to write the data. In conjunction with the nonlinear wavelength shift provided by a solid immersion lens, this method results in smaller bit sizes, thereby increasing the linear density of recorded data. The close proximity of the head to the material also allows for smaller magnetic-coil designs with faster switching times and faster seek times. (Courtesy TeraStor Corp.)

Company Information

Fujitsu Ltd.

Tokyo 100, Japan

Web: www.fujitsu.co.jp

Hitachi-Maxell

Fair Lawn, NJ 07470

(201) 794-5900

Fax: (201) 796-8795

Web: www.maxell.com

Matsushita Electric-Panasonic

Tokyo, Japan

(81) 03-3578-1237

Fax: (81) 03-3437-2776

Maxoptix Corp.

Fremont, CA 94538

(510) 353-9700

Fax: (510) 353-1845

Web: www.maxoptix.com

Sony Electronics

Park Ridge, NJ 07656

(201) 930-1000

Fax: (201) 358-4058

Web: www.sel.sony.com

TeraStor

San Jose, CA 95131

(408) 914-4185

Fax: (408) 914-4008

Web: www.terastor.com