DISPARATE TECHNOLOGIES FOR miniature displays STRIVE FOR DOMINANCE

DISPARATE TECHNOLOGIES FOR miniature displays STRIVE FOR DOMINANCE

Micromechanical structures, active-matrix liquid crystals, and emissive displays are vying to become the technology of choice for miniature flat-panel displays.

By Andrew Wilson, Editor at Large

Although flat-panel displays are competing with cathode-ray-tube (CRT) monitors for market share and their overall use is growing, microdisplays present another growth market for flat-panel displays. Indeed, according to a recent report, Miniature Display Markets, by

Business Communication Co. (Norwalk, CT), total shipments of microdisplays reached 432,000 units in 1998, a figure that is expected to reach 2.5 million units in 2003.

In the industrial market, microdisplay shipments accounted for approximately 136,000 units in 1998 but are also projected to grow by 25.8% and reach about 430,000 units shipped by 2003. Instrumentation, pro cess-control systems, and hand-held devices in combination are expected to drive the demand for these miniature displays. In addition, a variety of head-mounted displays are projected for development aimed at military and medical applications, according to the report.

"While Japanese man u facturers such as Seiko-Epson and Sony have taken the early lead with devices based on polysilicon-on-quartz backplanes," says Chuck McLaughlin of the McLaughlin Consulting Group (Menlo Park, CA), "more than ten US companies are now introducing competitive products."

Manufacturers building microdisplay products both here and overseas use a number of different technologies that can be categorized in three different classes (see table on p. 57). While Silicon Light Machines (Sunnyvale, CA) and Texas Instruments (TI; Dallas, TX) are pursuing micromechanical structures for building micro displays, others such as Kopin (Taunton, MA) and Displaytech (Longmont, CO) are using more-conventional liquid crystals. Although both display types are nonemissive, a third class of flat-panel devices, which is being developed by Planar Systems (Portland, OR), Micron Display (Boise, ID), and others, uses active-matrix or field-emission technology to generate images.

Micromechanical displays

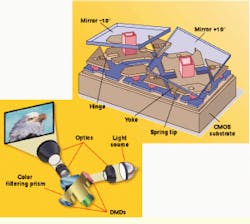

Although both the TI digital micromirror device (DMD) and the Silicon Light Machines grating light valve (GLV) are micromachined devices, each uses a different technology to display the image. The TI DMD uses an arrangement of micromirrors that modulate light; the GLV uses similar micromachined techniques to form pixels on the surface of a silicon chip (see Fig. 1). Each GLV pixel is made up of multiple ribbon-like structures, which are moved up or down over a fraction of the wavelength of light by controlled electrostatic forces. Because the ribbons are arranged so that each pixel is capable of either reflecting or diffracting light, an array of pixels can form a pattern of light and dark points on the surface of the chip.

To create a DMD display, developers take advantage of the reflective nature of the device by incorporating one DMD for each primary color (red, green, and blue) into their display design. As a result, the total reflective area is increased, and the projected image appears significantly brighter. Indeed, according to Texas Instruments, commercial systems built around the three-DMD subsystems have been demonstrated at more than 3000 lumens.

Using a combination of color splitting and combining prisms, dichroic interference filters are deposited on the surface of the DMD to split the light by reflection and transmission into red, green, and blue components. And, because light is directed to each DMD for the whole TV field, 10-bit gray scale per color is possible, allowing three-chip systems to reproduce 1024 shades of gray.

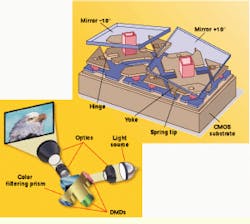

To create a GLV display, the device can be addressed in either digital or analog mode. In digital mode, pixels are switched between `on` and `off` states at speeds faster than the human eye can perceive. By varying the relative amount of time the pixel is on or off, levels of gray scale can be achieved.

In analog mode, driving circuits control the depth to which ribbons are deflected. When the ribbons are not deflected at all, the pixel is fully off. When the ribbons are deflected to exactly one-quarter the wavelength of incident light, the pixel is fully on.

Moving the ribbons to positions between these limits creates various shades of gray. In analog mode, the GLV yields a natural response that approximates the logarithmic response of the human eye, allowing the system to create film-like continuous-tone images. If a very bright light is used, GLV devices can be used as the display engine within a projection system. At the opposite extreme, by using low-power LEDs as a light source, GLV devices can be used as portable displays.

Active-matrix displays

Whereas Texas Instruments and Silicon Light Machines are pioneering micromechanical display devices, other companies are leveraging the benefits of mature integrated-circuit (IC) and liquid-crystal technologies. By using established wafer and liquid-crystal technologies, manufacturers such as Kopin, MicroDisplay (San Pablo, CA), Colorado MicroDisplay (CMD; Boulder, CO), and Displaytech are developing active-matrix liquid-crystal displays (AMLCDs).

Although many AMLCDs use red, green, and blue subpixels to create composite colors on a pixel triad, many microminiature display vendors are using field-sequential color techniques to produce all three colors on one pixel. In this way, a full-color image is produced in successive red, green, and blue images. All three subimages are produced at least three times faster than by a conventional CRT or thin-film-transistor display and are fused together by the human visual system into a full-color image.

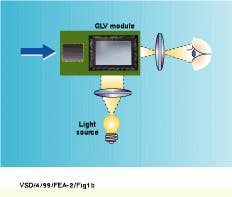

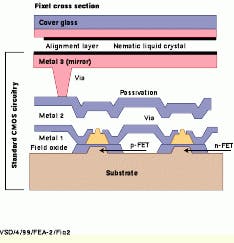

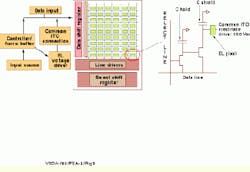

In the design of its CMD8X6P 0.47-in.-diagonal microdisplay, for example, Colorado MicroDisplay has developed a diagonal, active-matrix structure composed of crystalline silicon CMOS transistors that form individual pixels (see Fig. 2). These transistors drive nematic liquid-crystal material placed on top of closely packed mirrors. Analog pixel values are routed to cells by built-in row and column shift-registers operating synchronously with the pixel clock and control signals. The analog values create a voltage across the liquid crystals while polarized light reflects off pixel mirrors through the liquid crystal, a polarizer, and a viewing lens. According to CMD, this method enables a new class of microdisplays that are fast enough to produce time-sequential colors at frame rates that match those of CRT monitors.

Like the CMD 8X6P, the MD1024G5 MicroMonitor from MicroDisplay has also been optimized to run in field-sequential color mode. As a 1024 ¥ 768-pixel XGA-resolution display, the device operates in reflective mode and measures 0.63 in. diagonally. According to MicroDisplay, because this display is larger in area than VGA and SVGA displays, it is more useful in a projection application where display area affects the brightness of the projected image.

To produce field-sequential color for its LightCaster VGA display panel, Displaytech illumi- nates the ferroelectric liquid crystal (FLC) with red, green, and blue light-emitting diodes (LEDs). By ex ploiting the fast switching speeds of the FLC material, full color is achieved by sequentially displaying the individual bit planes for each primary color in rapid succession. Electrically, the VGA display panel functions as a write-only memory consisting of 640 ¥ 480 bits. Each memory cell switches the layer of FLC directly above it between two optical states. An external polarizer is used to produce "on" and "off" pixels.

To allow systems developers to rapidly incorporate microminiature displays into their products, many manufactures are offering development kits with their displays. For its CyberDisplay, a 320 ¥ 240-pixel, 0.24-in.-diagonal AMLCD, for example, Kopin offers an optical engine that includes an integrated display, backlight, and focusing mechanism. A solid-state back light is integrated with the display package in a single module to provide 20 fL of light for viewing the display.

Emissive displays

Of the two emissive types of displays vying for the microminiature display market, active-matrix electroluminescent displays (AMEL) and field-emission displays (FED) appear the most popular. Whereas AMEL technology integrates IC and thin-film EL (TFEL) technologies on a silicon wafer to produce a small display, FEDs consist of a matrix of emission devices, opposing a phosphor-coated transparent plate.

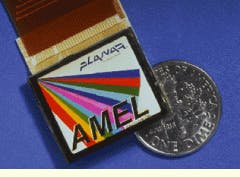

To build AMEL devices, Planar Systems overlays a thin-film, light-emitting EL structure on top of an IC wafer to produce a fully integrated emissive display (see Fig. 3). According to Planar Systems, the AMEL structure overcomes the size limitations of traditional TFEL technology by integrating the driver electronics onto the wafer to form a substrate for the device. Using this approach, Planar Systems has demonstrated AMEL displays with a resolution of 1000 lines per inch (lpi) in display formats of both 640 ¥ 480 and 1280 ¥ 1024 pixels. Additional AMEL displays have also been built with resolutions as high as 2000 lpi. Although the first AMEL devices were monochrome, color displays recently have been built that replace the single amber phosphor with a broadband "white phosphor" that derives the primary red, green, and blue colors by filtering.

While Planar Systems is pursuing AMEL displays, Micron Display (Boise, ID) and PixTech (Santa Clara, CA) are developing displays based on FEDs. Consisting of an x-y electrically addressable matrix of FEDs, these devices are driven by addressing and activating the FEDs to drive the electrons emitted by the FEDs toward a phosphor-coated transparent plate that serves as an anode. The phosphor on the faceplate is induced into luminescence as the electrons strike the phosphor.

Evaluation kits

FED manufacturers are offering evaluation kits for OEMs to develop products. The Micron Display CMP-FED evaluation module consists of a removable 0.55-in. FED and associated drive circuits. The module accepts NTSC video input and provides controls to adjust contrast, brightness, gamma correction, and black level. The CMP-FED display can be viewed directly or through standard 8X magnifying optics to simulate the view through the viewfinder of a camcorder, thermal imager, or head-mounted display (see Fig. 4). Complete with NTSC decoder circuits and fly-back transformer, a 1.3 ¥ 0.98 ¥ 0.935-in. display-evaluation board has been developed for portable applications.

PixTech also offers an evaluation kit for its FED technology. Dubbed the FE524-M2 display, the module consists of an FED panel connected to driver ICs, drive circuits, and a power supply packaged in a 132 ¥ 100 ¥ 11-mm metal can. To drive the display, a separate display controller board is installed into the user`s PC. According to PixTech, the controller board has the capability for frame-rate control, providing this display with eight shades of gray.

FIGURE 1. Whereas most microminiature displays rely on active-matrix liquid-crystal displays, others use novel microelectromechanical structures or emissive-display technologies. For example, Texas Instruments uses an array of micromirrors to modulate light in its digital micromirror device (top), and the grating light valve from Silicon Light Machines uses multiple deformable ribbon-like structures (bottom).

FIGURE 2. Colorado MicroDisplay has developed a diagonal active-matrix structure composed of crystalline silicon CMOS transistors that drive nematic liquid-crystal material placed on top of closely packed mirrors. This method allows the company to offer such devices as the CMD8X6P 0.47-in.-diagonal micro display.

FIGURE 3. Planar Systems overlays a thin-film, light-emitting electroluminescent structure on top of an IC wafer to produce a fully integrated emissive display. According to the company, the AMEL structure overcomes size limitations of traditional TFEL technology by integrating the driver electronics onto the wafer to form the substrate for the device.

FIGURE 4. Micron Display 0.55-in. CMP-FED flat-panel display is available as an evaluation module that consists of a removable display and associated drive circuits. The module accepts NTSC video inputs and provides controls to adjust contrast, brightness, gamma correction, and black level. Complete with NTSC decoder circuits and a fly-back transformer, the 1.3 ¥ 0.98 ¥ 0.935-in. evaluation board has been developed for portable applications.