Snapshots

Emerging industry on display

The China International Machine Vision Exhibition in Shanghai (March 22-24) showed the beginning of an industry in rapid growth to support a booming economy. The exhibition attracted approximately 3500 attendees-overwhelmingly from inside China-and 64 exhibitors. A concurrent forum on machine-vision technology and products featured speakers from several Chinese companies and institutions and foreign vendors. Zhang Qiang, deputy general secretary of the Chinese Mechanical Engineering Society (Beijing, China; www.cmes.org.cn), the show organizer, stressed the importance of machine vision to China’s growth.

Jeff Burnstein, executive director of the Automated Imaging Association (AIA; Ann Arbor, MI, USA; www.machinevisiononline.org) led a delegation of 15 AIA member companies attending the show and told the forum that the AIA was “very serious about working with the Chinese machine-vision industry.” Chinese exhibitors and attendees ranged from distributors of products from international vendors, to developers of original components and systems, to dedicated system integrators-and some were a combination of all three. Shanghai Kingtek (Shanghai, China; www.kingtek.net), for example, displayed a complete fastener-sorting machine that uses four Impact cameras from PPT Vision (Eden Prairie, MN, USA; www.pptvision.com) and has sold 10 to Chinese end users. Beijing JoinHope Image (Beijing, China; www.kjk.com.cn) exhibited a range of CCD and CMOS cameras, along with image-processing boards that included a new PCI Express-based model; a GigE camera will be release soon.

Shanghai Ruishi Machine Vision Technology (Shanghai, China; www.machinevision.cn) showed its EagleEye series of smart cameras and industrial digital cameras equipped with CCDs and a 32-bit TI DSP-based board. General manager David Shi said his company has had considerable success selling its cameras for traffic surveillance and bridge structural monitoring. They have not aggressively developed smart cameras yet because the market is not yet sophisticated enough for customer programming.

Color sensor checks auto plugs

At its Saarbrücken, Germany plant, automotive-parts manufacturer ZF Getriebe must inspect colored plugs used in transmissions to seal out water during a washing process. The plant produces approximately 4000 four-, five-, and six-speed transmissions a day, comprising 14 basic types with 120 variants. Production must be tightly organized, and every step in the workflow must be integrated.

To inspect these plugs at speeds up to 30/s, the company installed Simatic MV220 sensors from Siemens (Munich, Germany; www.automation.siemens.com). The sensors collect information solely from the colors of the plugs, which means the volume of data to be processed is very small-about 4 kbytes-and complex images can be read quickly. The 640 × 480-pixel sensor creates a data list after an image has been recorded. The list gives only the color spectrum and the brightness levels of the image. Each image is represented by its own unique cloud of dots, which the system compares to a reference image. The inspection results are processed at a central location and sent to an RFID data-storage device, which accompanies the transmission through final assembly.

AIA market study shows continued growth

A new study,Machine Vision Markets: 2005 Results and Forecasts to 2010, from the Automated Imaging Association (AIA; Ann Arbor, MI, USA; www.machinevisiononline.org), shows that 2005 was a good year for the machine-vision and imaging industry in North America and that continued growth is expected in 2006. Smart cameras saw the strongest growth in 2005, with a 19.1% increase in units and a 14.4% jump in revenue. Sales of application-specific machine-vision (ASMV) systems rose 13.6% in units and 6.4% in revenue. Fast-growing component markets included cameras, optics, and vision software.The 2005 North American market was $30.9 million for optics, $31.5 million for lighting, $75.6 million for cameras, $28.6 million for imaging boards, $20.4 for software, $99.2 million for smart cameras, and $1.18 billion for ASMVs.

The annual study, redesigned this year, says the 2005 worldwide machine-vision components market was $718.1 million, the smart-camera market was $380.9 million, and the ASMV systems market was $4531 million. The North American and European markets constitute 26% and 27.5% of the global market, respectively, and the Asian-Pacific market is 37%.

Beyond industrial automation, the study sees medical imaging and lab automation/drug discovery as the next largest opportunities, followed by nanotechnology, homeland security/biometrics, and advanced transportation systems. The study is available for purchase from the AIA.

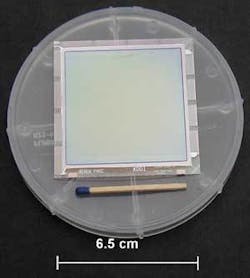

Sensor sees vertical color

A team of German and US scientists say they have made the first large-area (512 × 512) color sensor free of aliasing effects by stacking red, green, and blue imaging elements. The researchers come from the International University Bremen (Bremen, Germany; www.iu-bremen.de), Research Center Jülich (Jülich, Germany; www.fz-juelich.de), and the Palo Alto Research Center (Palo Alto, CA, USA; www.parc.xerox.com).

Rather than placing RGB filters over three separate pixels to render a single color pixel, the researchers have vertically integrated RGB thin-film layers consisting of amorphous silicon and its alloys. The spectral sensitivity of the sensors is controlled by the optical properties of the materials and applied bias voltage. Obvious applications include lab-on-chip systems, and the researchers are hoping to work with CMOS manufacturers to put the sensors on top of CMOS readout electronics for camera applications.