Adaptive lenses mimic the human eye

Conventional zoom lenses rely on mechanically moving groups of glass or plastic lenses to adjust focus, magnification, and field of view. Miniature adaptive lenses, however, offer the ability to change focal lengths while eliminating the need to mechanically change the location of the lens.

At the University of Central Florida (UCF; Orlando, FL, USA; www.ucf.edu), Shin-Tson Wu, provost-distinguished professor of optics, has developed a number of lens designs, some of which replicate the workings of the human eye. Wu was one of the first researchers to recognize the need for adaptive lenses, and he has directed research that has resulted in the development of both liquid-crystal (LC) based and fluidic lenses. LC lenses are based on the ability of liquid-crystal materials to alter their refractive index in the presence of an external electric field. With the appropriate selection of LC materials, substrates and device architecture, lenses can be created that adjust their focal length upon an applied voltage.

To market the technology, UCF has signed a licensing agreement with Holochip (Albuquerque, NM, USA; www.holochip.com) that gives the company exclusive worldwide rights to Wu’s adaptive lens patents, including five US patents and numerous foreign applications. Holochip has recently announced a commercially available adaptive polymer lens (see Fig. 1).

In one version, the layer’s refractive index is altered by varying the strength of the electric field in a concentric and graduated fashion. A change in the low voltage applied to a clear electrode modifies the focal length of the lens (see Fig. 2).

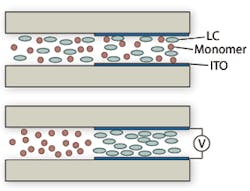

To accomplish this, a mixture of liquid-crystal molecules and smaller monomers are placed between two glass substrates coated with a layer of conducting indium tin oxide. A concave glass lens is then placed on top of one of the substrates. Without applying any voltage, the liquid-crystal/monomer is uniformly distributed throughout the substrates. After applying a voltage across the two substrates, however, the liquid-crystal molecules move to either end of the gap, where the electric field is higher, while the monomers move toward the middle, where the electric field is lower. Thus, the refractive index can be varied across the device allowing it to function as a lens.

Fluidic lens approach

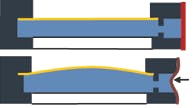

The second approach, which uses fluidic lenses, was inspired by principles of the human eye. In this approach, the lens comprises a transparent optical fluid encapsulated within a flexible lens membrane and substrate. Upon compression of the lens body, the shape of the flexible lens membrane is modified, which results in an adjustment of the focal length of the lens (see Fig. 3).

“The second approach,” Wu says, “relies on a transparent fluid-water or oil-that is encapsulated between a see-through, flexible membrane and a flat glass substrate. When a tiny servomotor compresses a circular periphery seal that acts like an iris diaphragm, the shape of the membrane grows convex, modifying the fluidic lens’s focal length.

Since this approach provides a wide range of focal power with almost no optical loss, it can be implemented in compact camera modules, making it attractive for size-limited applications. Likewise, the LC lens offers the ability to control high-order aberrations that can lead to blurriness, making it attractive in applications such as free-space optical communications, adaptive optics, corrective eyewear, and cameras.

At Sandia National Laboratories (Livermore, CA, USA; www.sandia.gov), Brett E. Bagwell and his colleagues have evaluated commercially available LC lenses from OKO Technologies (Delft, The Netherlands; www.okotech.com). In a nonmechanical zoom demonstration, Bagwell found that since these had limited dynamic range and aperture, the aperture of the system was limited to 55 (110 in the unzoomed case). And, because of the dispersive nature of these lenses, illumination was limited to monochromatic light. “Any chromatic aberrations limit the useable bandpass of an active optical zoom system that use these lenses,” Bagwell says.