CMOS SENSORS HELP dental imaging systems OUTPERFORM X-RAY FILM

CMOS SENSORS HELP dental imaging systems OUTPERFORM X-RAY FILM

By John Haystead, Contributing Editor

Many people have experienced the clenched-teeth tension, the heavy lead blanket, and the familiar buzzing that accompany the dental x-ray-machine imaging process. Most have also noted the x-ray operator moving safely away to escape radiation and energize the machine. Additionally, nearly all

can recall nodding blankly at white-on-black splotches on film

from which only the dentist could apparently discern the results of insufficient oral-care practices.

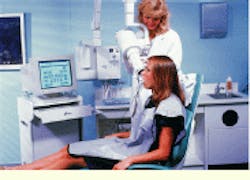

If this scenario isn`t familiar, it may be because you`re one of the 50 to 60 patients seen daily by Dr. Larry Kurzweil, a general dentist in Bellerose, NY. Dr. Kurzweil has not used x-ray film for four years. Instead, his patients view the current state of their teeth on large 19-in. color monitors, just seconds after they`ve been imaged by the Schick Technologies (Long Island City, NY) PC-based Computed Dental Radiography (CDR) system (see Fig. 1).

This CDR system provides real-time digital dental images based on higher dynamic range and signal-to-noise ratio than those produced by conventional x-ray film. And, once collected, the digital images can be manipulated and annotated using a variety of image-processing and record-management software tools. More important, the system`s 5-mm-thick CMOS imaging sensor needs as much as 90% less radiation than needed for conventional x-ray film.

According to Kurzweil, the reduction in radiation exposure has been the primary benefit of the CDR system to his practice. "We take maybe 200 to 300 x-rays a day and patients are very much aware of radiation hazards these days. The use of a system that dramatically reduces their radiation exposure has been a big draw for the practice," he says. Moreover, "fed up" with the drawbacks of conventional x-ray film, Kurzweil first began using CDR technology in one treatment room, but is now using the system throughout his practice.

In addition to health issues, however, Kurzweil points to the practical operational benefits of the digital imaging technology. "As opposed to going over a tiny piece of film with patients, I can colorize, point out, and explain things in a way the patient can readily see and understand" (see Fig. 2). Kurzweil also adds that he now no longer wastes time processing x-ray film only to find out the images are blurred, have to be retaken because of a wrong angle, or didn`t show the area of interest. Another major benefit has been on the administrative side, where the dental imaging system is used to help track and replicate patient image sets for insurance claims. "Because we can never send out [x-ray] originals, we`ve always had to duplicate everything. Now it`s a simple press of a button," Kurzweil adds.

He acknowledges that the initial start-up investment needed for a CDR system might seem high for some dentists--individual CMOS sensors range in price from $5000 to $6000. However, he says, "this is quickly recouped when you take into account the cost of a person`s time to develop x-ray film. With the CDR, a hygienist or assistant can accomplish the same task in a few seconds."

CMOS sensor

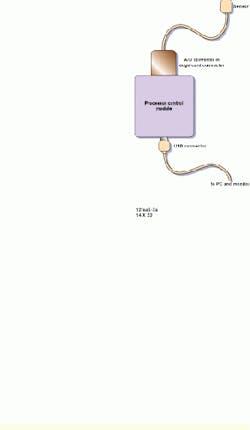

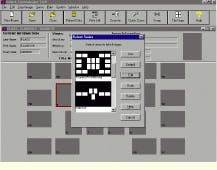

The CDR system essentially consists of a sensor, remote-control processor module, PC-host computer, and application software (see Fig. 3). The key enabling technology is the active-pixel-sensor (APS) technology developed jointly with the Jet Propulsion Laboratory (Pasadena, CA) and now manufactured commercially by Photobit Corp. (Pasadena, CA).

Unlike charge-coupled-device (CCD) sensors, APS sensors are produced using standard CMOS fabrication techniques, which can integrate additional functional circuits on the same chip. The CMOS design also provides a 100-times reduction in system power requirements relative to CCDs. Moreover, because CCDs are essentially capacitive devices, they require external control signals and large clock swings (5 to 15 V) to achieve acceptable charge-transfer efficiencies. These off-chip circuits dissipate large amounts of power.

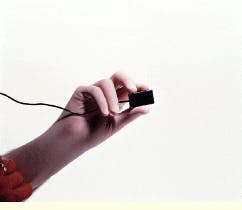

The APS chip is contained within the CDR imaging sensor, which is placed directly into the patient`s mouth in the same way as a conventional x-ray film assembly. The sensors can be cold-soaked or gas sterilized between uses, and they come in different sizes corresponding to standard x-ray films for generating bitewing, periapical, pedo, and pediatric images. Within the sensor, the APS pixels are spaced at a 40-mm pitch, and the total number of pixels are proportional to the size of the sensor. According to Eric Fossum, Photobit chief scientist, Schick`s largest CMOS chip now in production is a 645 ¥ 900 APS array that measures 37 ¥ 27 mm.

A scintillator material first converts the x-ray stream to light energy, which, in turn, is detected by the APS. Each sensor pixel contains a photodetector element and active timing control, sequencing, and signal-readout transistor circuits. These devices convert the integrated charge into a voltage within each pixel. The voltages are then read out over an x-y interface rather than via the charge-domain shift register used in CCDs. ©

Modular design

The APS array generates an analog signal stream that is fed into a 12-bit analog-to-digital (A/D) converter located within the edge connector of the sensor. Although his company also offers APS sensors with integrated 8- and 10-bit A/D circuits, Photobit`s Fossum says it`s currently more cost-effective to use an off-chip A/D converter for the dental imaging application because of the high bit resolution required. The system readout rate is about 500 kHz, which means that about 1 s is needed to transfer all the pixel data from the sensor. This slow-scanning process reduces noise for better image quality and reduces costs by allowing the use of a slower-speed version of the high-resolution A/D converter.

In the latest CDR-2000 system, the digital data are passed into a remote preprocessing and control module that also serves as a universal serial bus (USB) adapter. This module incorporates a Kawasaki LSI (San Jose, CA) RISC 48-MHz processor that runs with integrated USB-control firmware. The processor, which includes 4 Mbytes of off-chip buffer memory, performs several formatting operations on the data before passing it directly to the PC host through the USB port.

As pointed out by Schick Technologies president and chief executive officer David Schick, "The remote USB module design is a big improvement over earlier versions of the CDR," which required an internal PCI-interface board in the computer. The remote module can be used with any USB-capable Windows-95/98-based computer, although Schick recommends the Windows 98 version.

The remote module processor controls and triggers the sensor by detecting when the x-ray impulse has occurred as well as manages the readout process and communications with the host computer. Although much of the company`s processing architecture is proprietary, Schick acknowledges that the module processor contains a "fair amount of embedded software," which handles most of the image pre-processing and filtering functions. For example, a reference frame of essentially dark-signal data is taken together with every frame of live image data. The remote-module processor correlates and subtracts this dark data from the actual image set before passing it to the PC. ©

Next, the Pentium-based host computer performs a nonlinear transform on the image data, reducing it from 12- to 8-bit data. According to Schick, this nonlinear data reduction gives the images a more film-like appearance. "Film is logarithmic, and, although we don`t actually do a logarithmic transform, we do something similar." The resultant digital images are the result of a dynamic range of 4096:1 and an overall diagnostic accuracy that Schick claims is "comparable to or slightly better than a perfectly exposed and developed film."

Image management

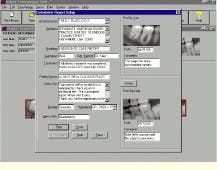

The CDR system`s 32-bit Windows-compatible application software provides full control over the digital sensor and lets the dentist manipulate the digital x-ray images with a variety of built-in processing tools. These tools permit the correcting of underexposed radiographs and the taking of calibrated measurements. Viewing functions include zoom, contrast, and colorization as well as a "QuickZoom" mode that allows dentists to view an entire series of images in the same way that they would visually examine conventional film using a loupe (see Fig. 4).

A softening/sharpening function can be used to filter any extraneous noise generated by the x-ray head. After image collection, a suite of management and annotation tools allows the dentist to select, edit, and annotate the series with clinical comments before saving them onto disk (see Fig. 5). Although the CDR sensors can be used with most modern x-ray systems, the x-ray source must be adjustable to a very low exposure time (0.04 s or less).

Schick Technologies usually supplies a computer as part of the system package to dentists. "Most dental offices don`t have computers, and depending on the size of the dental operation, we provide anything from a single-user laptop to a wide-area-network solution." The CDR software is compatible with both server-based and peer-to-peer networks, such as Novell and LANtastic, as well as with several third-party dental practice management software packages.

Schick is awaiting FDA approval of a new digital panoramic x-ray imaging system. The PanorX system can be fitted to a range of existing panoramic x-ray machines, and, similar to the CDR system, it replaces x-ray film images with real-time images. Unlike the CDR, however, the PanorX is a time-delay-integration CCD system that is integrated with the host computer via a PCI-card interface. As described by Schick, "Adaptability was a big challenge of this system`s design because every panoramic x-ray system is mechanically different."

From his perspective, Kurzweil predicts that within ten years x-ray film will be a thing of the past in dentistry. "Patients don`t want to be exposed to excess radiation and will expect [a higher] level of technology from their dental-care providers. Ultimately, digital imagery will have as big an impact on dentistry as the high-speed handpiece."

FIGURE 1. Using a 19-in. color monitor, the Schick Technologies PC-based Computed Dental Radiography (CDR) system provides real-time digital dental images with 90% less radiation and a higher dynamic range and signal-to-noise ratio than those achieved by conventional x-ray film. After storage, the digital images can be manipulated and annotated using a variety of image-processing and record-management software tools.

FIGURE 2. The dental-imaging computer monitor (right) can display a full-mouth series of dental x-ray images simultaneously (left). This full set of radiographs includes horizontal bitewings.

FIGURE 3. The CDR system essentially consists of an active-pixel CMOS sensor, a control processor module, a host personal computer, and application software (top). Built to fit in a patient`s mouth (right), the active-pixel sensor is produced using standard CMOS fabrication techniques. It provides a 100-times reduction in system power requirements and works with 90% less radiation relative to CCD sensors.

FIGURE 4. The entire dental image can be enlarged for closer examination or a specific area can be magnified or zoomed to evaluate a possible defect (top). In addition, a color mode can assign specific colors to different density levels in the x-ray image or highlight significant anatomical landmarks such as a mandibular canal (bottom).

FIGURE 5. In addition to choosing a supplied viewing format from a menu such as full-mouth-series, bitewing series, or an endodontic grid series (left), dentists can create their own format for displaying radiographic images. Similarly, the dental imaging system allows dentists to create and customize reports with radiographs embedded directly on the report (right). Reports might include notes with the radiographs, treatment plans, prognoses, and future recall visits