Improving Cold Chain Logistics: Eutecma's Reusable EPS Box System

What You Will Learn

- The inspection system combines machine vision, RFID, and cleaning to facilitate the reuse of EPS boxes, reducing waste and environmental impact.

- High-resolution stereo cameras and pattern projectors enable detailed 3D inspection, ensuring defect detection accuracy for pharmaceutical safety.

- RFID chips track each box's lifecycle, including cleaning cycles and damage history, supporting efficient inventory management.

Food and pharmaceuticals often must be sent in temperature-sensitive containers, which can lead to sustainability issues. Discarding expanded polystyrene (EPS) boxes after a single use is wasteful, especially as these companies will continue needing boxes for the same purpose. Cold chain company eutecma GmbH (Mannheim, Germany) aims to change that, through its retecma refreshment program. The program analyzes boxes using machine vision, cleaning them to keep them in the rotation.

“There was a need for a future solution to significantly reduce CO2 emissions and save raw materials and energy,” says Markus Kirstein, head of special machinery and information technology at eutecma.

The cold chain company created its retecma division for customers to return their boxes for cleaning, reuse, or recycling.

Related: Focus on Vision: Robotic Paint Inspection, Battery Detection | June 20, 2025

Getting the system right was important, as one pharmaceutical shipment in these boxes could contain €100,000 of medications. “The boxes will be used in cold chain and pharmaceutical applications. There is no acceptance for errors,” says Kirstein.

In the summer of 2022, eutecma began collaborating with phil-vision GmbH (Puccheim, Germany), which specializes in machine and computer vision. The integrator conducted a feasibility study and selected components to use.

Envisioning and Developing a Machine Vision Solution

The cold chain company wanted a solution where the 4-liter to 1,588-liter boxes could arrive at the refreshment facility unsorted, to be quickly scanned, analyzed, cleaned, and reused—or sent for recycling. The vision system would be key to this process; eutecma needed a solution that was durable, reliable, repeatable, and had high performance.

phil-vision experimented with time of flight (ToF) and LiDAR technology, but eutecma found that automatic calibration for the five LiDAR systems was not exact enough for their needs, says Kirstein. Also, “the precision of ToF in general was not good. There also was the risk that we would have to check dark or near to black boxes in future, which is a problem for this technology.”

It was important for eutecma to distinguish between types of defects, artifacts, and any material deviations. The system looks for boxes containing defects that are > 5 mm. If defects are not correctly detected, those parts can pass inspection or good parts can be rejected, distorting material flow and resulting in customer complaints.

How The Permanent Solution Works

Here’s how the system, which began operation in May 2024, works. eutecma equips each EPS box with an RFID chip, containing machine-readable information with the box model, including its type, weight, and number of past cleaning cycles. The tag remains on the box throughout its lifecycle.

Related: Automate 2025: Machine Vision Technology Galore in Demos of Industrial Processes

When a box arrives, it is scanned and registered automatically into the retecma system. It is placed on the rollers, where it is weighed, to help identify any missing material from the modular components. It is then examined by a camera system phil-vision designed, generating a point cloud. Using artificial intelligence, the system processes the point cloud and imports the reference model to compare the box to the appropriate 3D CAD model, while checking the box’s outer shell for damage.

If the box passes inspection, it is cleaned with UV light irradiation and with steam cleaning if needed. It is then returned to the usage cycle. Boxes failing the weight or optical inspection due to damage or a defect, are sent for the appropriate recycling process.

The 3D Approach Using Stereo Vision and Pattern Projectors

phil-vision provided eutecma with five fully calibrated stereo sets. Each set has two 20 MPixel GigE camera heads (a left and right camera). The total system also includes five pattern projectors, with green light, using a fixed randomized pattern One projector was installed between every stereo set. The stereo cameras connect through the GigE Vision interfaceThey were calibrated using Halcon image processing software from MVTec (Munich, Germany).

Related: How TI Fluid Systems Improved its Steel Strip Inspections

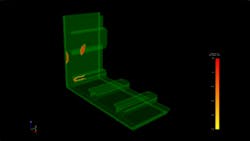

The box is visioned by all five stereo sets and then the system, using the Halcon software, merges data from the box into a point cloud to create a 3D image. It then matches and checks point distances against the appropriate model, in software developed by phil-vision, on an IPC connected via PROFINET. The system reduces the point density to decrease processing time.

The stereo sets are mounted 1550 mm from the transport rollers and cover an area approximately 200 x 160 cm. The cameras capture the boxes from four angles above, plus straight down. “We have a huge, big field of view. Every box can be seen from all sides,” Kirstein says.

The software processes the images “with several filters to remove flying pixels and evaluate if the presence of a point makes sense at a certain position,” Kirstein says, before processing the point cloud. For defects, the system also rates point accumulations. “Deviations are always on the same layer so we can check against additional deviated models and see which model results in the smallest error.”

The Results Achieved by Combining Stereo Cameras and Pattern Projectors

A key advantage of stereo cameras combined with pattern projectors is the high degree of flexibility in analyzing the materials, says Kirstein. In addition to needing a machine vision solution with sufficient resolution to capture the various box sizes, he wanted the possibility of capturing darker color boxes in the future.

Related: Nestle Automates Inspection of Plastic Scoops in Adult Nutrition Products

While retecma is using 3D processing for all its needs, it can easily switch to 2D processing. The system provides flexibility, allowing contrast and color to be used at full resolution, in addition to the depth information.

The final retecma solution includes not only the machine vision system, but RFID technology, weighing, UV-C irradiation, steam cleaning, and cloud technology integrations.

If a customer reprocess/reuses one medium-sized solution (a Euro pallet shipper) 15 times, eutecma estimates the process saves around 1,000 kg of CO2. In addition, damaged components can be replaced, as the cooling box system is modular, providing further material savings.

The retecma system is being used in Ludwigshafen, Germany, and in Springfield, Ohio, though eutecma plans to make it available in more than 30 locations globally.

About the Author

Deborah Abrams Kaplan

Freelance Journalist and Author Deborah Abrams Kaplan covers tech topics and manufacturing/supply chain for clients including Manufacturing Dive, Supply Chain Dive, Forbes, Fast Company, Kyndryl, GE Healthcare, Johnson Controls, ServiceNow, P&G Signal360 and DHL. You can see her work at www.kaplanink.com.