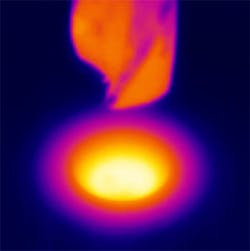

Thermal cameras help perform nondestructive testing

A UK-based stress analysis consultancy firm is using thermal imaging cameras to perform strain and fatigue performance tests.

Established in 2004, Strain Solutions (Chesterfield, UK) is using Micro-Epsilon’s (Ellesmere Port, UK) thermoIMAGER TIM160 inline radiometric thermal imaging camera to conduct the tests, using the camera to detect very small changes in the temperature of materials or components as they are bent, fabricated or work-hardened.

Powered and operated via a USB 2.0 interface, the camera provides the engineers at Strain Solutions with temperature images and profiles of a target area. The unit is supplied with a software package called TIMConnect that enables the engineers to configure all device parameters, as well as enabling the real-time capture (at 120 Hz full frame rate) and storage of images or video of an event for slow-motion playback at a later date.

Strain Solutions’ managing director Dr. Richard John Greene, who has experience working with nitrogen-cooled thermal imaging cameras for the military, initially discovered Micro-Epsilon’s TIM160 at a trade exhibition in the UK in 2009.

“I was looking for a camera which would enable us to do comparable nondestructive test work I had already performed with high-specification, cooled infrared detector systems but at a price that was affordable. The two critical factors for me in selecting the TIM160 were the camera’s fast response rate and thermal resolution per pixel for a microbolometer array,” says Greene.

Rather than supplying the TIM160 with a single factory-calibrated optical lens, Micro-Epsilon offers users the option of a developer kit that includes three interchangeable lenses (6, 23 and 48 degree FOV).

For R&D test engineers who may be unsure of which applications they will use the device for, the three interchangeable lenses cater to a range of fields of view for temperature monitoring tasks.

-- by Dave Wilson, Senior Editor, Vision Systems Design