MACHINE-VISION SOFTWARE: Vision framework supports multiple software packages

System integrators often rely on individual software packages from well-known vendors such as Cognex (Natick, MA, USA), Matrox Imaging (Dorval, QC, Canada), and National Instruments (Austin, TX, USA). Being familiar with the functions of these software packages allows developers to craft different machine-vision applications more rapidly.

Sometimes specific image-processing algorithms are not available in single software packages, requiring the developer to code those functions in high-level languages and integrate them into the final application.

However, if developers could select a number of algorithms from multiple software packages and integrate them using an icon-based graphical user interface (GUI), this process could be simplified. Indeed, this is one of the concepts behind the VisionServer 7.0, a machine-vision framework from ControlVision (Auckland, New Zealand; www.visionserverframework.com), a productivity tool to develop and deploy machine-vision applications quickly.

First shown at VISION 2011 show in Stuttgart, the software allows open source image-processing libraries from AForge.NET, OpenCV, and Point Cloud Library and commercially available packages such as VisionPro Software from Cognex to be used together in an integrated graphical development environment.

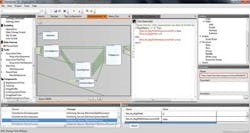

By exposing the functions of these packages as graphical elements, developers can drag and drop sequences of image function blocks onto a graphical desktop to develop entire applications using labeled functional blocks (see figure).

These blocks can contain representations of vision software functions and supported cameras such as those from Basler (Ahrensburg, Germany), Allied Vision Technologies (Stadtroda, Germany), PixeLink (Ottawa, ON, Canada), Cognex, SICK (Waldkirch, Germany), and Sony (Park Ridge, NJ, USA).

To date, ControlVision has implemented systems using the software in the meat, packaging, electronics, solar, pharmaceutical, food and beverage, and plastics industries. Seeing even more potential in emerging application areas such as medical, surveillance, and agriculture, the company is now offering the VisionServer software to system integrators, machine-vision specialists, OEMs, and researchers.

One of the first systems designed with the software has been implemented by Automation & Robot Technologies (A&RT; Penrith, Australia) for Kraft Foods (Mt. Gambia, South Australia). According to David Berry, managing director of ControlVision, the standard date code-inspection system has the capability to inspect date codes, timestamps, and other characters in less than 100 ms.

At the heart of the system is a Cognex In-Sight 5603 vision sensor with optical character verification (OCV) capabilities. Combined with the ControlVision VisionServer HMI framework and a CompactLogix programmable logic controller (PLC) from Allen-Bradley (Milwaukee, WI, USA), the system can be integrated into existing line controls using discrete I/O, field-bus systems, and/or Ethernet protocols. Third-party SCADA systems can also be configured to collect production data from the Ethernet PLC and directly from the Cognex vision sensor if required.

The open architecture of the A&RT system means that quality control checks can be customized and extended with application-specific requirements. This may include data collection from other inspection devices such as additional vision sensors used for label inspection or cap/closure inspection, or x-ray or metal detectors.

ControlVision's VisionServer provides a common HMI for the camera, PLC, and reject system. The HMI can be customized—without the need to program—and supports multiple user access levels. This allows staff members to be restricted or granted access to specific adjustments and settings of the inspection system, ensuring quality control criteria are only modified by qualified staff members.