Vision System Clears Codes on Cans

Paul Wilson

Checking that batch codes on the underside of beverage containers have been accurately printed might seem like a relatively trivial application for a vision system. However, when the system must inspect alphanumeric dot-matrix batch codes and dates on the shiny concave bases of beverage cans at high speed, the inspection task becomes more challenging.

This was the application faced by Diageo, a beverage company that required the automation of an inspection on a canning line that processed up to 20 cans/sec after the bases of the cans had been printed by an alphanumeric coder. To accomplish this, Diageo enlisted the expertise of Scorpion Vision Ltd., a developer of 2-D and 3-D vision inspection systems based aroundScorpion Vision software from Tordivel.

Inspecting codes

To perform the task of alphanumeric dot-matrix batch codes and date inspection, Scorpion Vision developed an inspection station enclosed in a stainless-steel housing located downstream from the character printing station. This housing contains the vision system that inspects the cans prior to packaging and palletizing.

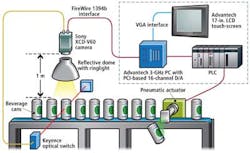

Inside the inspection station, a vertically mounted XCD-V60E, VGA 90-frames/sec FireWire 1394b camera fromSony is placed approximately 1 m above the cans to capture images of the codes as they travel through the station (see Fig. 1).

The presence of a can is detected by an optical sensor fromKeyence mounted across the path of the cans. Once the path of the optical switch is broken, the optical switch triggers the camera and the captured image is transferred over the FireWire interface to a 3-GHz Pentium-based industrial rack-mounted PC from Advantech running the Scorpion Vision software. This software then performs an analysis to verify that the correct code has been marked onto the base of the can.

Several key issues needed to be overcome during the development of the system. After experimenting with several direct lighting techniques, it was discovered that none of them could light the curved, mirrored surface of the can base in a uniform enough fashion to allow an image of the code to be captured by the camera.

The solution was to employ a semispherical reflective dome with a fluorescent ringlight mounted inside it that projects light onto the bottom of the cans. The diffuse light reflected from the dome's shaped interior surface then homogenously illuminates the curved surface of the can. The camera is then placed 15 cm atop the dome, through which it can capture an image of the code on the can.

Fail safe

The initial specification called for the system to send a signal to an Allen-Bradley PLC if it was unable to detect the code on the underside of the can. In turn, the PLC would trigger a pneumatic actuator to eject the can from the production line. As the development work continued, however, it was decided that the system should operate in a fail-safe mode. Thus, the system was reconfigured so the PLC would eject a can from the line only if it did not receive a signal. The system's fail-safe design prevents cans with missing codes from being passed as a consequence of the failure of the vision system.

Originally, Scorpion Vision chose to interface the digital output of the PC via an Ethernet cable to a standalone external Advantech "Adam" D/A to produce the 17-V signal required to trigger the PLC. Due to the speed of the inspection process, it was discovered that the response time of the external Adam D/A unit was not fast enough to continuously trigger the PLC each time a can passed inspection. The external Adam D/A unit was replaced with an Adam 1730 PCI-based, 16-channel D/A converter. Embedded in the PC, rather than connected to it via an Ethernet cable, the converter could generate the analog signal fast enough to trigger the PLC.

Positioning the optical trigger was also important. Because of the close proximity of the cans as they pass through the inspection station, initial attempts to differentiate one can from another by focusing the beam on the side of the can were unsuccessful. There was no gap between the cans that enabled the beam to be broken. The solution was to move the optical trigger higher up, thereby creating an optical pathway that would be broken by the space between the cans where their sides are crimped inward (see Fig. 2).

Software development

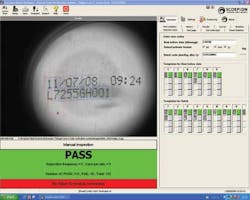

The application to identify and verify the presence of the codes was developed using Tordivel's Scorpion Vision software. This software comprises a development environment that sports a toolbox of image-processing algorithms, which allow developers to create a custom vision-based solution and ahuman machine interface (HMI) that enables the machine's operators to visualize and control inspection processes.

To inspect the alphanumeric codes on the base of the beverage cans, apattern-matching tool needed training to recognize a particular letter on the base of the can. An image of the base of the can is first captured and the specific letter of interest highlighted. The pattern-matching software traces the line of the pixels around the edges of the letter, after which it creates a polygonal shape that represents the character. To improve the verification task, the software also creates line elements by analyzing the patterns of the individual blobs that make up the characters, after which it can identify the angle between them, such as the 90° angle between the line elements that form an "L" (see Fig. 3).

The data are imported into a pattern-matching tool where they are used as a reference. Once trained to identify the specific letter on the base of the can, the software then identifies the location of all the other "best before" date and batch numbers on the can that have been printed relative to it. Finally, the software verifies their accuracy.

During changes of batches of beverages on the production line, the coder that prints the alphanumeric codes onto the cans was physically removed from the line. Once reset and returned to the line, this created slight differences in the shape of the printed codes. To resolve this disparity, the software was programmed to recognize a number of minor character variations. To do so, two templates were created—one for the "best before" date numbers and one for the batch codes. These templates can be created by machine operators by selecting the characters to train at the beginning of a batch.

The templates contain a set of one or more representative images of the letters or numbers for both the "best before" date and the batch numbers that are printed on the cans. These templates, which are displayed on an Advantech 17-in. LCD capacitive touch-screen monitor, can be selected by the operator to verify the letters or numbers printed on the can during the inspection process.

The system, which is now in use in the canning facility, allows Diageo to perform verification of the codes on the beverage cans. It can also halt the canning line to enable the operator to determine whether there is a fault with the printer or the vision system if a series of failed readings is detected. By collecting statistical data, the performance of the canning line can be monitored over a period of time, highlighting how many cans have passed or failed inspection.

Paul Wilson is managing director at Scorpion Vision Ltd. (Lymington, UK).

******

Machine vision inspects marks on auto parts

Direct part marking (DPM) of a Data Matrix symbol on the surfaces of parts enable them to be tracked throughout their entire lifecycle. Successful DPM systems reliably decode these symbols; by monitoring symbol quality such systems can gauge how well the DPM equipment is performing. A smart camera or Data Matrix verifier mounted by the marking equipment can signal an operator when the quality of the symbol begins to deteriorate. The operator can make the necessary adjustments before it impacts production and parts need to be scrapped.

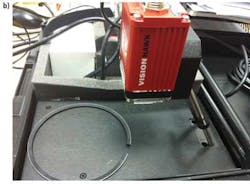

After engraving a Data Matrix symbol and alphanumeric characters on the surface of automotive gaskets, one Chinese-based automotive parts manufacturer is using a smart camera to either read the characters, decode the symbol, or both simultaneously (see figure). If the letters are missing, incomplete, or poorly marked, line workers will not know the model of the gasket or where it should be installed. More important, certain critical gaskets need to be tracked through the product's lifecycle, and so must be clearly marked for reliable decoding.

Having reviewed several options, the manufacturer chose a Vision Hawk machine-vision smart camera and integratedAutoVision software from Microscan (Renton, WA, USA). After decoding the mark, data are recorded into and tracked within the manufacturer's production data-acquisition system.

By directly marking and tracking each part and component, the company can search the history and information of any given part at any time within its lifecycle. Because of the integrated features of the Vision Hawk camera, no additional purchase of lighting, lenses, or specialized software was required, resulting in equipment cost savings. —Dave Wilson, Senior Editor

Company Info

Advantech

Cincinnati, OH, USA

Allen-Bradley

Milwaukee, WI, USA

Diageo

Runcorn, UK

Keyence

Woodcliff Lake, NJ, USA

Scorpion Vision Ltd.

Lymington, UK

Sony

Park Ridge, NJ, USA

Tordivel

Oslo, Norway