Multi-camera vision system inspects cars for dents caused by hail

A German company called adomea (advanced optical measurement and automation) has developed a multi-camera vision system that is used to quickly inspect vehicles for hail damage, which helps to accelerate the claim process for insurers and vehicle owners.

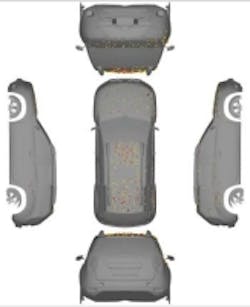

Called MIKo (a German acronym for mobile identification system for vehicle surface defects) uses a total of 17 cameras, which are mounted in different positions to capture the entire exterior of a vehicle. The reflection patterns of the vehicle’s surface are observed, MIKo delivers an objective measurement result on a metric scale. In order to detect even the smallest irregularities and distortions on the surface, the system uses high-resolution cameras from Allied Vision.

MIKo uses the Manta G-609 GigE camera, which features the 6 MPixel Sony ICX694 CCD image sensor, which achieves frame rates of 15 fps at full resolution. The system also uses the Manta G-917 GigE camera, which features the 9 MPixel Sony ICX814 CCD image sensor with EXview HAD II technology, which can achieve frame rates of 10 fps at full resolution.

René Franke, Managing Director of adomea in Bochum, told Allied Vision that the cameras have to run on Power over Ethernet, so that each camera only uses one single cable. Additionally, Franke noted, only GigE Vision cameras would work, because of the cable length necessary to perform the task.

All of the cameras in the portable device are synchronously controlled using PTP (Precision Time Protocol) and together are used to generate a complete image of the vehicle being examined. Using Allied Vision’s Vimba software development kit, the cameras are integrated into damage analysis software developed by adomea where 3D renderings for nearly 90% of the highest-sold auto models over the last ten years are stored. Results, specifically the individual dents, can be subdivided not only according to shape and depth, but also can be designated according to the corresponding section of the chassis. MIKo also provides a visual representation of the damage in an automatically-generated damage report. Using the available interfaces, common damage calculation software can be connected.

Frank notes that the damage assessment takes two-to-three minutes, and in another two-and-a-half minutes, the results are logged and available.

There are currently five mobile MIKos ready for use across Germany, which can be deployed anywhere hail damage occurs. When a system is deployed, adomea works cooperatively with the insurance company. How much the entire damage assessment, calculation, and regulation process can be completely digitized is currently undergoing lively debate throughout the industry, suggested Allied Vision. As of now, the scanner serves to support experts in most cases, and has not completely taken over the evaluation process.

"Confidence in an adjuster’s expert option increases when he or she makes use of modern imaging and measurement technology," according to Franke.

Additionally, the MIKo system from adomea has been adopted in the United States as well, but instead of using an aluminum frame construction, a large truck is used which can be set up and parked at the location of need. The measurement chamber’s area has been adapted and increased in size to accommodate American pickup trucks.

Looking toward the future, adomea is already developing new models and is planning to use a 29 MPixel camera from Allied Vision. In future models, adomea hopes that the system will be able to detect small surface flaws such as scratches and rock impacts, in addition to hail damage.

View more information on Allied Vision.

View more information on adomea (German only).

Share your vision-related news by contacting James Carroll, Senior Web Editor, Vision Systems Design

To receive news like this in your inbox, click here.

Join our LinkedIn group | Like us on Facebook | Follow us on Twitter

About the Author

James Carroll

Former VSD Editor James Carroll joined the team 2013. Carroll covered machine vision and imaging from numerous angles, including application stories, industry news, market updates, and new products. In addition to writing and editing articles, Carroll managed the Innovators Awards program and webcasts.