Flat dome lights tame reflections and shadows in machine vision

Joe Gugliotti and Marc M. Landman

Illumination plays a critical role in capturing the high-quality images needed for successful machine vision solutions. Different parts and inspection tasks have different requirements for lighting. There has been considerable innovation in recent years in LED lighting technology, driven in large part by growing demands from users building more compact vision systems and inspecting difficult parts such as those with shiny, uneven surfaces.

Providing diffuse illumination over small and large areas, the patented flat dome light from CCS Inc. (Kyoto, Japan; www.ccs-grp.com) solves many of the mechanical challenges encountered when trying to image parts within clear plastic packages, highly specular parts, and packages that have oddly shaped reflective surfaces.

Related: Polarization 101: Concepts, techniques, and technologies

Traditionally, imaging applications that require diffuse lighting to mitigate point-source reflections rely on standard dome lights and large light panels with a camera hole. While these lights suit many applications, the flat dome light eliminates the mechanical constraints often encountered when using these lighting methods, making it especially advantageous for compact vision systems and where added flexibility in working distance and degree of light collimation is useful.

What is a flat dome light?

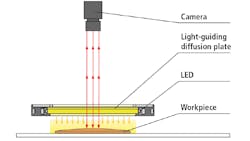

The flat dome light is a 10 to 16 mm thick flat light panel with a window that looks completely clear. The camera looks through the flat dome, so the distance from the camera to the light and to the object being inspected is not constrained by any mechanical limitations (Figure 1).

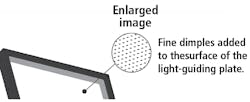

It is an edge-lit light with a dense array of very small reflectors on the glass that direct the light downward across the entire surface (Figure 2). Additionally, no point-source of light exists to create reflections off the object being imaged because the light exits downward at all angles everywhere across the glass surface.

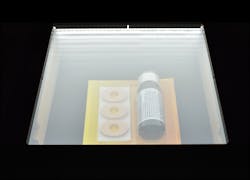

Like other approaches to creating diffuse lighting, the flat dome light typically sits just above the object being inspected so that the light hits the object from all angles (Figure 3). However, without the camera hole to constrain the light’s position above the object, by raising the height of the light, one can collimate the light more and enhance certain features on the object (Figure 4). Doing so makes the light behave more like a coaxial light source, but without the light loss caused by the two trips through the half-mirror of a coaxial light.

Advantages over standard dome or diffuse light panel options

Flat dome lights have the primary advantage over standard dome or diffuse light panel options due to the lack of a camera hole that a camera needs to look through. Because of the flat dome light’s clear surface, the working distance is not limited by the physical height of the standard dome or the vertical position of the diffuse panel light.

This flexibility in the camera’s working distance (Figure 5) means the most ideal lens can be used for imaging through the flat dome light.

The lack of a camera hole also eliminates dark spots from the camera hole appearing in the image, whether on the object or in the background. With a traditional dome light, this dark spot can be overcome by adding a coaxial light on top of the dome (Figure 6). Naturally, this adds cost, takes up extra space, and requires the coaxial light to be controlled and matched to the dome separately.

Earlier versions of the flat dome light had limitations that sometimes resulted in the appearance of light reflectors (dot pattern) in the captured image. The solution was to ensure that the flat dome light was not within the camera’s depth of field.

The latest generation of the light offers an improved light guiding plate containing a dense pattern of tiny micro-dimple reflectors. The new design virtually eliminates this problem, yielding the advantages of a traditional dome light in a compact format without the camera hole drawback (Figure 7). The new generation flat dome light, as a result, suits today’s high-resolution image sensors quite well.

LFXV flat dome lights often deploy into applications where reflections or surface irregularities need to be minimized. This article presents a variety of typical industrial inspections where the flat dome light can turn a very difficult inspection into an easy one.

Sample images, imaging through clear packaging

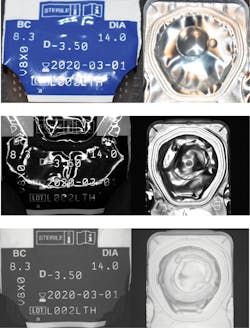

Sample images of randomly purchased packaged products were first captured with a CCS diffuse ring light and subsequently, the CCS flat dome light (Figure 8). These images have not been optimized but provide examples of possible image improvements. The angular and round plastic packaging virtually disappears, facilitating inspection of the contents for assembly, feature, or package verification.

In the case of a consumer product, the flat dome image can be used to ensure all the items have been packaged. For blister packs, the flat dome not only enhances the appearance of each blister, it minimizes the texture of the package’s surface, permitting the vision system to use the registration and tear here marks to locate each blister’s expected position (Figure 9).

Imaging a portion of a small cylinder

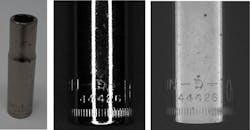

Avoiding unwanted reflections off a metallic or shiny cylindrical surface when trying to capture an area scan image of features on the cylinder, such as character strings or barcodes, proves to be quite a difficult machine vision task. It becomes even more difficult when the surface of the cylinder or the features of interest on the object vary in the consistency of their appearance.

In this example, enough of the round chrome socket can be imaged by the camera to verify the stamped digits present on the object (Figure 10). The characters themselves do not reflect the light, as seen with the ring light.

Imaging highly specular objects

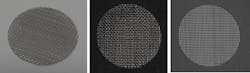

When capturing images of a wire-mesh screen, the flat dome light eliminates the specular highlights across the scene, providing an improved image for a machine vision system (Figure 11).

The screen can be better inspected for damage or inconsistent spacing of the strands. The flat dome light minimizes the effect of surface texture variation, especially on metallized film surfaces, to permit the underlying features to be properly imaged for automated inspection.

The lot and date codes on the foil surface become fully inspectable when using the flat dome light (Figure 12). The contact lens itself can be detected as present.

Imaging a PCB

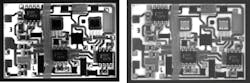

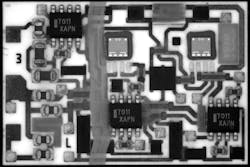

The flat dome light also offers an effective solution for imaging printed circuit boards (PCB). The example below shows how this light removes glare and enhances or reveals image detail not visible with alternative lighting (Figures 13 and 14).

Numerous colors and sizes

Available in sizes ranging from 25 x 25 mm up to 300 x 300 mm, the flat dome light can deploy into machine vision applications involving many different part and conveyor sizes (Figure 15). Additionally, the flat dome light is available in four different color options: red, white, blue, and infrared, with green available on request.

Related: Filtering techniques eliminate Gaussian image noise.

King of the domes

With its versatility, the flat dome light offers systems integrators a bright, shadow-free illumination in a compact form factor. Furthermore, the light offers ease of integration and has fewer restrictions in terms of the camera height above the light. Lacking a camera hole, the flat dome light provides high uniformity and no dark spot images without an add-on light source.

With the latest optical design, the nearly invisible reflector pattern enables clearer, brighter image capture, even with larger depths of field. The result? Many machine vision applications that were previously difficult to solve can now be addressed.

Joe Gugliotti is President of R.J. Wilson Inc. (Chelmsford, MA, USA; www.rjwilson.com) and Marc M. Landman is a Senior Technical Advisor at CCS America (Burlington, MA, USA; www.ccsamerica.com).