Imaging tool combines camera, optics, and lighting

For semiconductor inspection, many systems integrators require small assemblies that combine imaging cameras with light-emitting-diode (LED) lighting devices. To meet these demands, several vendors, including Cognex Corp. (Natick, MA; www.cognex.com) and DVT Corp. (Norcross, GA; www.dvtsensors.com) have developed higher-cost "smart" cameras with LED lighting.

At this year's Photonics Boston, the Electronics Division of Cohu Inc. (San Diego, CA; www.cohu-cameras.com) presented a different approach. The company offers a low-cost modular imaging tool that integrates a 768 × 494-pixel, RS-170, ICX-419 DLA, monochrome, 1/3-in. CCD from Sony Electronics (Park Ridge, NJ; www.sel.sony.com) with programmable LED lighting.

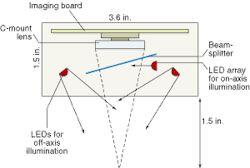

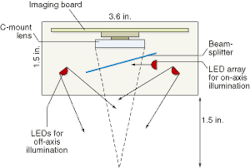

According to Steve Weir, Cohu senior OEM sales engineer, the integrated imaging tool measures 3.65 × 3.65 × 1.5 in. and fits in small, tight assemblies required by printed-circuit-board developers and semiconductor-inspection applications. It comes with a 10.5-mm-focal-length, f /14 C-mount lens on the CCD camera to provide a focal length of 1.5 in. below the imaging tool (see figure). A small, fixed aperture in the light path increases the depth of field. Since this imaging tool can be easily modified, the aperture size can be increased to f /1.5 to gain increased criticality of focus. To provide off-axis illumination in the x-y direction, the imaging tool contains an array of red LEDs tilted towards the focal point of the lens. Although the standard imaging tool includes 680-nm LEDs, any LED wavelength from blue to infrared can be manufactured and tuned to the camera package.

"In numerous machine-vision applications," says Weir, "it is necessary to illuminate the scene using on-axis illumination." To provide this illumination, the Cohu 1200 Series imaging tool incorporates a beamsplitter in front of the optic. In this way, LEDs located in the z-plane of the imager can reflect light on the same axis as the camera. To produce even illumination, the complete unit is covered with a frosted plastic covering. After installing the imaging tool in a machine-vision system, the lighting can be programmed using a programmable power supply.

At Photonics Boston, Cohu showed the imaging tool attached to a programmable power supply that provided an independent 12-V output to the x-, y-, and z-axes LEDs. "By attaching the programmable supply to a host computer over an RS-232 interface," says Weir, "the developer can control the type of illumination using a custom graphical user interface or one built using off-the-shelf packages such as National Instruments (Austin, TX; www.ni.com) LabView software."