LED lamps sharpen lighting and optics for accurate imaging

Light-emitting-diode lamps provide a more-uniform light source, offer a longer lifetime, and consume less power than incandescent or fluorescent lamps.

By Andrew Wilson, Editor at LargeSystem developers insist that choosing the correct type of lighting is the most critical aspect of designing a machine-vision system. Fortunately, several types of illumination methods are available to meet the needs of complex illumination demands. These methods use fiberoptic, fluorescent, and light-emitting-diode (LED) lamps that are integrated into ringlights, spotlights, backlights, diffuse lights, and linear lights.

A recently introduced illumination approach based on LED lighting offers machine-vision developers a number of benefits over conventional lighting techniques. Light-emitting-diode lamps provide a uniform, flicker-free source of light and run cooler, offer a longer lifetime, and use lower voltage and less power than incandescent or fluorescent lamps. Moreover, monochromatic LED lighting results in less lens aberration and produces sharp and consistent image quality.

In another recent illumination development, imagers are combining lighting, lens, and camera in a single package for machine-vision applications requiring automated identification or x-y positioning.

Lighting techniques

Different LED lighting products are used in machine-vision systems to improve the quality of the captured image and to highlight defects in the inspected parts. These products implement front lighting, ring lighting, diffuse backlighting, and darkfield illumination.

FIGURE 2. With a rated lifetime of 100,000 hours, the Advanced Illumination DL2449 axial diffuse illuminator provides illumination over a 50 x 50-mm aperture. Available in several LED configurations, including an RGB version, the illuminator includes a dust cover to protect its beamsplitter.

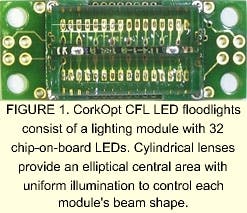

For objects where the presence or absence of surface features must be inspected, direct front lighting is mostly used. To provide this illumination, manufacturers such as CorkOpt (Cork, Ireland) have developed a line of LED modules. In its CFL Series, for example, CorkOpt has incorporated a lighting module with 32 chip-on-board LEDs and combined them with special optics. Designed for use in pairs or multiples, each module's beam shape is controlled by a cylindrical lens to provide an elliptical central area with uniform illumination (see Fig. 1).

Direct front lighting, however, can produce an image with excessive contrast. In such cases, important object features could be hidden by dark or bright areas in the image. Adding diffusers, though, can reduce the contrast and clarify the object's features. On the other hand, the light intensity might be reduced. Then, the systems developer must add more illumination to the object under inspection.

Adding diffusion

Adding diffusion to LED lighting is easily accomplished. Numerous illumination methods exist that reflect LED light to achieve optimal lighting conditions for inspecting different types of objects.

For example, the axial-diffusion method uses light rays that reflect off a beamsplitter directly onto the object. In this approach, specular surfaces perpendicular to the camera appear illuminated, while surfaces at an angle to the camera appear dark. Nonspecular surfaces absorb light and appear dark. Manufacturers offering such lighting products include Northeast Robotics (Weare, NH), Metaphase Technologies (Medford, NJ), and Advanced Illumination (Rochester, VT).

Rated with a lifetime of 100,000 hours, the Advanced Illumination DL2449 axial-diffuse illuminator provides light over its 50 x 50-mm aperture. Available in several LED configurations, including a red-green-blue (RGB) version, the device includes a dust cover to protect the unit beamsplitter (see Fig. 2).

For imaging applications requiring a greater uniformity of diffuse illumination, Northeast Robotics has developed a square continuous-diffuse illuminator (SCDI). The SCDI unit operates using the same lighting principles as does the company's diffuse on-axis light (DOAL) unit, but light rays reflect off both a beamsplitter and a lower chamber; in this approach, the solid angle of illumination is increased. Tilting the light parallel to the beamsplitter increases the illumination uniformity of non-planar surfaces (see Fig. 3).

Applications requiring an even surface illumination for reflectance measurements—such as in determining the color of flat surfaces—often employ integrating spheres. Designed for such applications, the Northeast Robotics Nerlite cloudy day illuminator (CDI) is useful for compact disk artwork verification and the inspection of solder patterns on circuit boards.

The Advanced Illumination DL7248 diffuselite is also based on a modified integrating sphere. Like the company's axial diffuse illuminator, the diffuselite offers a 100,000-hour lifetime and includes an integrated camera light source.

Stocker & Yale (Salem, NH) has also developed a range of LED illumination products. They include red LED 1-1/2-in. spotlights, 2 x 2-in. backlights, and custom line arrays. According to product manager Joe Diruzza, strobe and white light versions will follow these products. For greater diffuse illumination, the company also plans a range of axial illuminators.

Measuring outlines

For measuring objects, inspecting board through-holes, counting edge features, and calculating areas, LED backlighting finds widespread use. A number of vendors including Advanced Illumination, FarPoint Innovations (Eden Prairie, MN), and Illumination Technologies (East Syracuse, NY) offer LED backlights that provide a range of active areas.

Illumination Technologies offers the P/N 5622-CW LED mini-backlight with a 0.8 x 1.0-in. active area and the P/N 5632-CW backlight with a 2.25 x 2.25-in. active area. Both devices feature a lifetime of greater than 100,000 hours, a uniformity of ±10%, and an active wavelength of 660 nm.

Because many transparent objects are not visible when using diffuse backlighting, system developers light the object's edges so that they appear bright against a dark background to improve image contrast. Such darkfield illumination is achieved by projecting a cone of light from behind the transparent object so that light diverges from the optical axis and is not imaged. Only the light scattered or reflected by the object is directed into the optical axis and imaged.

Both Dolan-Jenner Industries (Lawrence, MA) and Advanced Illumination produce LED illumination systems that produce darkfield effects. Whereas Dolan-Jenner's Darkfield Illuminator adapts to the company's A3739-P ringlight, Advanced Illumination's RL2115 darkfield illuminator ringlight is a stand-alone unit targeted at the inspection of small objects requiring intense illumination. Designed to operate from either 12 or 24 Vdc, the RL2115 is supplied with 2 m of cable and connectors and weighs 3.2 oz (see Fig. 4).

Circular lighting

In many microscope-based systems, LED ringlights provide an even illumination when small objects or small areas of large objects need to be examined. Such ringlights provide shadow-free, on-axis lighting and are useful for imaging highly reflective objects. To further reduce specular reflections from shiny surfaces, ringlights can also be used in combination with polarizers (see Vision Systems Design, May 1999, p. 9).

FIGURE 5. Because many machine-vision applications, particularly those involving automated identification or x-y positioning, use a fixed field of view, a fixed focal length, and a specific light, Northeast Robotics developed a line of Machine Vision Imagers (MVis) that combine lighting, lens, and camera in one package. To date, MVis for darkfield, diffused on-axis, and continuous diffuse illumination have been developed. Shown is the diffuse on-axis illuminator with a ring imager.

With an expected lifetime of 70,000 hours, the ILP ringlight from Volpi (Schlieren-ZÜrich, Switzerland) is typical of the LED ringlights available from Illumination Technologies, Metaphase Technologies, and Seiwa Optical (Woodcliff Lake, NJ). Available with white, red, and near-infrared (NIR) LEDs, the ILP ringlight can be used at 50- to 70-mm working distances and consumes between 3.6 and 5.8 W depending on which LED lamp is chosen.

Lights, camera, action

Even though lighting is the most important design consideration in developing a machine-vision system, lighting vendors are aware that they must still add value to their products to compete effectively. At the same time, they are simplifying the design decision of which lighting, lenses, cameras, software, and vision processor to use.

Because many machine-vision applications, particularly those involving automated identification or x-y positioning, use a fixed field of view (FOV), a fixed focal length, and a specific light, Northeast Robotics recently introduced its line of Machine Vision Imagers (MVis). These imagers combine lighting, lens, and camera in a single package.

To date, these MVis use darkfield, diffused on-axis and continuous diffuse illumination units (see Fig. 5). To produce a multiaxis imager (MAXi), the lighting geometry is combined in a single unit (DOAL and darkfield). In the MVi series, the FOV ranges from 6 to 32 mm, and the stand-off distance runs from 25 to 150 mm. In all, more than 30 combinations of MVi products can be produced from four mechanical packages.

As systems integrators are looking to OEM lighting suppliers for systems solutions, it is likely that lighting and illumination manufacturers will continue to introduce innovative products. Last month, for example, CCS America (Waltham, MA), a subsidiary of CCS Kyoto, Japan), opened its headquarters in the United States. According to its vice president James O'Hanley, the company plans to offer more than 200 standard LED products, including ring, darkfield, linear, diffuse, and strobe lights.

Company Information

Advanced Illumination

Rochester, VT 05767

Web: www.advancedillumination.com

CCS America

Waltham, MA 02453

Web: www.ccsamerica.com

CorkOpt

Cork, Ireland

Web: www.corkopt.com

Dolan-Jenner Industries

Lawrence, MA 01843

Web: www.dolan-jenner.com

FarPoint Innovations

Eden Prairie, MN 55344

Web: www.farpointinnovations.com

Illumination Technologies

East Syracuse, NY 13057

Web: www.illuminationtech.com

Metaphase Technologies

Medford, NJ 08055

Web: www.vramp.net/~szeto/

Northeast Robotics

Weare, NH 03281

Web: www.nerlite.com

Seiwa Optical

Woodcliff Lake, NJ 07675

Web: www.seiwa-optical.com/

Stocker & Yale

Salem, NH 03079

Web: www.stkr.com

Volpi

Schlieren-Zürich, Switzerland

Web: www.volpi.ch