Hyperspectral vs Multispectral Imaging: Choosing the Right Solution for Industrial Inspection

What You Will Learn

- Hyperspectral imaging provides high spectral resolution and adaptability, ideal for complex applications requiring detailed spectral analysis.

- Multispectral imaging offers high speed, moderate cost, and sufficient accuracy for many industrial inspection tasks, making it suitable for large-scale deployment.

- Adding wavelengths increases costs and reduces throughput, so selecting the appropriate system depends on the specific application needs and spectral complexity.

- LED-based illumination enhances spectral imaging performance by improving stability, uniformity, and environmental safety compared to halogen sources.

Are you designing an inspection application that requires more spectral information than is possible using visible wavelengths? If so, you will likely be met with a decision: whether to employ hyperspectral or multispectral imaging.

Applications such as quantitative chemometric analysis or identifying complex foreign material often demand additional wavelengths, particularly in the infrared and ultraviolet ranges, to reveal information invisible to the human eye. However, adding extra wavelengths adds costs both in the form of hardware and decreased throughput, creating a trade-off between performance and practicality.

Whether you require the straightforward multispectral approach or the more nuanced and complex approach that hyperspectral imaging can provide comes down to the task at hand.

This article explores the benefits and limitations of each approach and shows how, in some applications, a well-specified multispectral imaging system can be almost as effective as hyperspectral but at a lower cost and higher speeds.

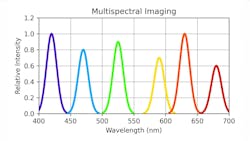

Multispectral Imaging

In multispectral imaging, a sensor captures an image with a number of different wavelengths. The most common form is color photography, which captures red, green, and blue wavelengths. In machine vision applications, infrared wavelengths add more visual information by unlocking features not visible to the human eye. Capturing the same image with multiple wavelengths is achieved by one of two approaches:

- Sequentially pulsing a light of a specific wavelength while exposing the camera sensor to capture multiple images of different colors

- Using filtering optics to make certain parts of the camera sensor sensitive to a narrow wavelength range. This allows multiple different wavelengths to be illuminated at the same time.

Related: Researchers Capture Multispectral Images Without a Lens or Color Filter

In industrial applications, line scan imaging is a go-to approach for high-speed, high-resolution inspections. A single line sensor will give a grayscale value and wavelength information is recovered by knowing which wavelength of light is illuminated during exposure.

For multispectral imaging, this would require a sequence of different wavelengths. Adding wavelengths increases inspection time as each requires a separate exposure. The limitation can be mitigated using multiline cameras, which have a number of single line sensors with filtering optics to make each line sensitive to a specific wavelength range.

This is typically an RGB trilinear sensor, or RGB+IR quadlinear sensor. This would allow red, green, blue, and infrared wavelengths to be illuminated at the same time rather than requiring four individual exposures.

Advantages of Multispectral imaging

There are multiple advantages of multispectral imaging including the following:

- High speed: Line scan cameras now are capable of speeds in the 100s of kHz.

- High spatial resolution: CMOS cameras can now be 32k pixels in a single line, allowing inspection of very fine detail.

- Moderate cost: Multiline cameras, while more expensive than single line cameras, are significantly cheaper than hyperspectral cameras.

Limitations of Multispectral Imaging

Multispectral imaging has some shortcomings including:

- Limited adaptability: Adding new applications/models can be difficult as the system has a limited number of wavelengths, and adding wavelengths requires hardware changes.

- Moderate accuracy: With a limited number of wavelengths available, more complex applications that require the recognition of subtle spectral differences can prove challenging.

Related: How Hyperspectral Imaging Is Changing Inspection and Material Analysis

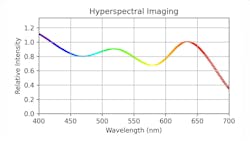

Hyperspectral Imaging

Hyperspectral imaging extends multispectral’s range by capturing hundreds of narrow, continuous wavelength bands, typically 1-4 nm apart, providing near-spectrometer spectral resolution for each image pixel. This makes it one of the most powerful machine vision tools on the market, allowing the combination of the chemometric analysis of a spectrometer and the image analysis algorithms of machine vision. This allows identification of the most complex foreign material along withthe analysis of substances like sugar or fat content in one vision step in the process.

Given the vast number of wavelengths involved, a sequential strobing approach is unfeasible from a timing perspective because it would take too long to pulse hundreds of different wavelengths. Engineers often solve this problem by using filtering optics to subdivide a wide wavelength range on a sensor.

The most common form of hyperspectral imaging is a line scan-based approach colloquially known as “push-broom” imaging. Here a line is imaged through a slit, before going through some sort of refractive/diffractive optic to split the spectrum, and this is then projected onto an area-scan camera sensor. Now the x-direction of the sensor is still spatial (capturing the line being imaged) but the y-direction is now spectral (each line receives a different constituent part of the spectrum).

Advantages of Hyperspecrtral Imaging

The advantages of hyperspectral imaging include the following:

- Highly adaptable: New applications/models can be added to the system very easily, as all wavelengths are available from the beginning

- High accuracy: the closest thing to a lab-based spectrometer combined into a vision system, leading to the most accurate results for the most challenging applications.

Limitations of Hyperspectral Imaging

The limitations of hyperspectral imaging include the following:

- Low speed: As a line scan camera that uses an area scan sensor at its core, it is limited to 100s of Hz associated with standard area cameras

- Low spatial resolution: As it is based on an area sensor, the resolution is limited to the horizontal component of this sensor, which is usually much shorter than traditional line scan sensors. Average horizontal resolution is around 1k pixels

- High cost: Hyperspectral cameras are some of the most expensive cameras on the market, which can act as a high barrier to entry.

Comparative Analysis Case Study

While hyperspectral imaging offers unparalleled spectral detail, multispectral imaging can often deliver equivalent insights when carefully optimized for the application. The following case study demonstrates this using a real-world experiment from food quality control.

Hyperspectral SWIR spectroscopy is a powerful chemometric tool, with many molecular bonds having absorption peaks and overtones present in the 1000-1750 nm range. This allows for the identification/tracking of common compounds like water, sugars, fats, and proteins.

Related: SWIR Imaging Enables Many Types of Machine Vision Applications

With many chemists accustomed to using full spectrum results to do their analyses, it is often appealing to use hyperspectral imaging to re-create these broadband, high spectral resolution results. This level of detail often isn’t often required for machine vision applications, so we can perform basic analysis very quickly using one or two wavelength bands.

Many of these analyses require small batch destructive testing, where a small sample of the overall batch is sampled, and tested in a destructive manner to acquire spectral results. hyperspectral and multispectral imaging allow full-batch, non-destructive testing, i.e., every item can be scanned and tested in a way that doesn’t damage it. This makes machine vision a great tool for many QC departments in industries like food and pharmaceuticals.

Take for example chocolate, the globally beloved confectionery treat. Everyone has their favorite variety and flavor, be it white, milk or dark.

Cocoa percentage is what dictates that bitter/sweet balance that people subjectively enjoy. High-end chocolatiers will sell bars advertising a certain concentration of cocoa, which appeals to those who are particular about how bitter the chocolate is. Quality control is important here to ensure consumers get what they pay for. Producers will want to make sure that a 75% cocoa bar is as close to that recipe across the full batch as possible.

Related: Harnessing UV-C LEDs for Advanced Inspection and Quality Control

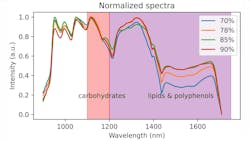

Chocolate—as a blend of cocoa solids, cocoa butter, sugar and milk solids—produces distinct NIR/SWIR absorption features. C–H bonds (lipids, cocoa butter) have overtones around ~1200–1750 nm and sugars and carbohydrates show features near 1100–1200 nm. Meanwhile, some polyphenol/phenolic bands have been reported in the 1350–1700 nm region (Veselá, 2007). As ingredient ratios change it should be possible to monitor the spectral impact and use that to estimate the cocoa percentage.

For this study, a team at ProPhotonix collected a series of different chocolate bars, containing either 70%, 78%, 85% or 90% cocoa. After scanning several pieces of each one, the mean spectra can be analyzed. The plot in Figure 4 shows the raw intensity curves (left) and the normalized curves (right). The compounds that are affecting the differences in the spectra are highlighted.

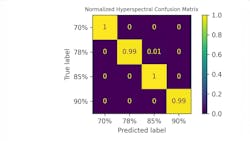

Using the data collected, we trained a machine learning model to recognize the different formulations. When evaluating the model on unseen data, it gave near perfect classification, with an F1-score of 0.99 (1 being perfect ability to differentiate all data accurately).

Following this analysis, a multispectral study was done using six SWIR LEDs, those being 1100 nm, 1200 nm, 1300 nm, 1450 nm, 1550 nm, and 1650 nm. Like the hyperspectral study, a series of scans were taken of the different chocolate samples, but this time each scan would only have six spectral data points, rather than the hundreds provided by the hyperspectral camera.

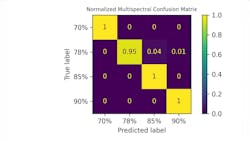

This achieved an F1-score of 98.63, only ~1% worse than the hyperspectral approach. In Figure 6, we show the confusion, or error, matrices resulting from both approaches, showing just how similarly each perform at predicting the classification. The only chocolate formulation that suffers from switching to multispectral is the 78%.

LED vs Halogen

Lighting is often an overlooked factor in spectral imaging performance. The shift from halogen to LED-based illumination has transformed system stability, safety, and efficiency. All images in this study were captured using an LED based hyperspectral line light system. For hyperspectral imaging, traditionally halogen-based bulbs are used; however, using an LED based system provides a number of benefits:

- Increased lifetime: This means more uptime and fewer maintenance costs.

- Increased stability: The halogen spectrum will shift over the lifetime of the light, leading to misclassification or requiring the models to account for this drift. LED sources are very stable over their lifetime.

- Increased spatial uniformity: Closely spaced chip-on-board LEDs produce a highly uniform line across the illumination, whereas halogen suffers from fall-off on the edges of the illuminated area.

- Low heat generation: Halogen bulbs generate a lot of heat, meaning they can be fire hazards for certain products (cardboard, paper etc.) and unsuitable for others (. raw meat & chocolate).

- More environmentally friendly: Halogen bulbs are slowly being phased out due to environmental concerns

When performing multispectral imaging, halogen is not a viable option as the light cannot be strobed at a high speed, which is a fundamental technique for multispectral imaging.

Related: Effective Lighting Design Strategies for Reliable Machine Vision Applications

The multispectral approach outlined in the case study required six wavelengths, which may be hard to maintain at a fast throughput. By taking advantage of the latest advancements in multispectral cameras, this analysis could be done with three exposures by using a bilinear SWIR camera. In these cameras, there are two InGaAs lines, with optics to make one sensitive to light <1375 nm and one >1375 nm, meaning that the two wavelengths can be exposed at once essentially doubling throughput potential.

Conclusion

Selecting the right vision system ultimately depends on the complexity of the analysis and the requirements of the application. While hyperspectral imaging offers unmatched spectral resolution, a carefully designed multispectral configuration can achieve comparable results in many industrial settings at significantly lower cost and higher throughput.

For most vision laboratories, hyperspectral imaging remains invaluable for research and wavelength selection, while multispectral systems deliver the efficiency and reliability needed for large-scale deployment.

About the Author

Fabien Dubois

Fabien Dubois, PhD, an application engineer at ProPhotonix (Boston, MA, USA), completed his doctoral work in photonics in the Tyndall National Institute (Cork, Ireland). Since graduating, he has worked for FoodMarble Digestive Health (Dublin, Ireland) in the medical device industry and Tomra (Dublin, Ireland) in the food sorting industry. At ProPhotonix, Fabien uses his expertise in physics and machine vision to help customers find the best lighting solution for their application.